LO-5-2350-262-12 - Page 1 of 27

LUBRICATION ORDER

LO 5-2350-262-1 2

8 November 1993

SUPERSEDES L05-2350-262-12, 26 JUNE 1992

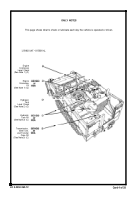

ARMORED COMBAT EARTHMOVER

(ACE), M9

Reference: TM 5-2350-262-10, TM 5-2350-262-20-1, -2, TB 43-0210, and Supply Catalog C9100-IL

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes, or if you know of a way to improve the

procedures, please let us know. Mail your letter or DA Form 2028 (Recommended Changes to

Publications and Blank Forms) directly to: Commander, U.S. Army Tank-Automotive Command, ATTN:

AMSTA-MB, Warren, Ml 48397-5000. A reply will be furnished to you.

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited.

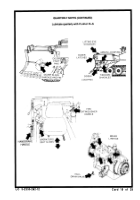

This lubrication order is divided into six sections, based on lubrication intervals (daily, monthly, quarterly,

semiannually, annually, and on-condition).

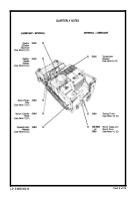

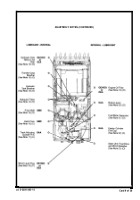

An overall view showing lubrication points precedes each set of detailed notes.

A dotted leader line (- - - -) means there are lubrication points on both sides of the vehicle.

Intervals are based on normal operation.

.

Lubricate more often during constant operation.

l

Relubricate all items found contaminated after fording, swimming, or high-pressure washing.

l

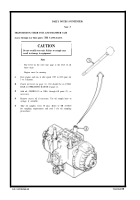

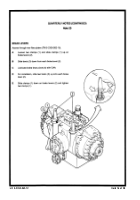

On-condition intervals for oil changes shall be determined by the Army Oil Analysis Program (AOAP)

laboratory and shall be applied unless otherwise notified. See card 3 for oil sampling procedures.

l

Oil filters shall be changed at prescribed hardtime intervals or sooner when:

a. They are known to be contaminated, or clogged;

b. Service is recommended by AOAP laboratory analysis.

.

For equipment under manufacturer’s warranty, hardtime oil service intervals shall be followed. Intervals

shall be shortened if lubricants are known to be contaminated or if operation is under adverse conditions

(such as longer-than-usual operating hours, extended idling periods, extreme dust).

l

WARNING:

Drycleaning solvent (SD-2) is toxic and flammable. Wear protective goggles and gloves,

and use only in well-ventilated area. Avoid contact with skin, eyes, and clothes, and do not breathe

vapors. Do not use near open flame or excessive heat. If you become dizzy while using drycleaning

solvent, get fresh air immediately, and get medical aid. If contact with skin or clothing is made, flush with

water. If contact with eyes is made, wash your eyes with water, and get medical aid immediately.

.

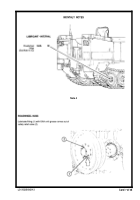

For operation of vehicle in prolonged cold temperatures below -10~F (-23~C): remove lubricants prescribed

in the key for temperatures above -10~F (-23~C), clean parts with drycleaning solvent (SD-2), and

relubricate with lubricants specified in the key for temperatures 0~F to -65~F (-18~C to -54~C).

l

Operation in dusty or sandy areas requires more frequent cleaning and servicing of filters to prevent dust

from entering engine, transmission, steer unit, and hydraulic system.

MAN-HOUR TIMES

The man-hour time specified is the time you need to do all the services prescribed for

a

particular interval.

These times are based on normal vehicle operation.

LEVEL OF MAINTENANCE:

l

C – - Operator

l

O – – Unit Maintenance

LUBRICATION POINTS

Type of lubricants used at each point are identified by arrows:

PL

GAA

OBSERVE THE FOLLOWING:

l

NEVER

use the wrong type grease.

l

NEVER

use too much lubrication.

l

ALWAYS

clean grease fittings with drycleaning solvent (SD),

type II or equivalent, and dry before lubricating.

l

ALWAYS

use the lubrication order.

Approved for public release: distribution Is unlimited.

Back to Top