TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 192 of 528

TM 9-2330-356-14

(2)

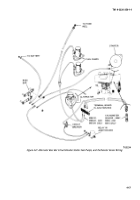

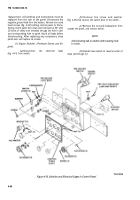

Oil Pressure Switch (Fig. 4-35).

(a)

With engine stopped, disconnect the two

leads from the oil pressure switch.

(b)

Attach a continuity tester to the two

terminals on the switch. Have an assistant turn over the

engine several times. As oil pressure builds and exceeds

13 psi, the switch will close.

(c)

Watch the continuity tester. At first

there should be no continuity reading. As the switch

closes, a continuity reading can be observed on the tester.

If no reading is obtained, the switch is defective and must

be replaced.

TA502347

Figure 4-35. Location of Oil Pressure Switch.

(3)

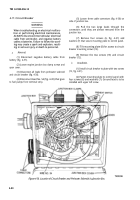

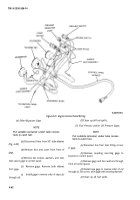

Fuel Stop Solenoid (Fig 4-36).

(a)

With an external 12V source connected

to solenoid switch terminal, check operation of plunger

and current draw.

(b)

Current draw with the plunger up

should be about 1 amp. If it is much more, the contacts did

not close and solenoid should be replaced.

c.

Replacement of Low Oil Pressure Switch.

(1) Remove engine shroud cover.

(2) Disconnect the two leads (fig. 4-35) from the

switch. Unscrew the low oil pressure switch.

TA502348

Figure 4-36. Location of Fuel Stop Solenoid.

(3) Apply a thin layer of pipe compound (item 26,

Appendix E) to new low oil pressure switch. Tighten

securely. Reconnect the two leads to switch.

(4) Replace engine shroud cover.

4-23.

Battery and Cables

WARNING

When troubleshooting an electrical malfunc-

tion or performing electrical maintenance,

ALWAYS disconnect Intervehicular electrical

cable from semitrailer, and negative battery

cables at batteries. Failure to follow this warn-

ing may create a spark and explosion, result-

ing in serious injury or death to personnel.

NOTE

Refer to FM 9-207, Operation and

Maintenance of Ordnance Material in Cold

Weather (0° to -65 ‘F) for Information on

maintenance of batteries In extreme cold.

a.

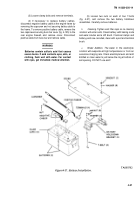

Removal.

(1) Remove two wingnuts and washers (fig. 4-37)

securing battery cover to battery holddown assemblies.

Remove cover.

(2) Disconnect negative, then positive battery

cables from terminals.

4-56

Back to Top