TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 216 of 528

TM 9-2330-356-14

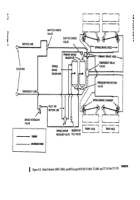

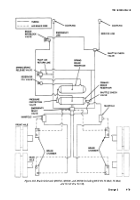

g.

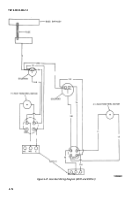

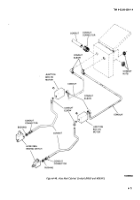

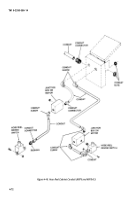

Brake Interlock (M970A1 including M970 SN TC-

0843, TC-0844, and TC-103 thru TC-178).

The brake interlock

system is activated when the door on the hose reel cabinet is

open. When actuated, the interlock valve sends air from the

rear reservoir into the service air line. This gives a service

signal to the emergency brake relay valve. The relay valve

releases air from the rear reservoir to the brake air chambers to

apply the brakes. Figures 4-56 and 4-58 show how the

interlock system connects into the air brake system

h.

Slack Adjusters.

These convert linear motion of

the brake chamber to rotating motion of the camshaft.

The slack adjuster consists of a housing, two gears, and

two gear covers. Brake adjustments are made through the

slack adjuster.

4-33.

Service Brake Shoe Assemblies, M967,

M969, and M970 except M970 SN TC-0843,

TC-0844, andTC-103 thru TC-178.

a.

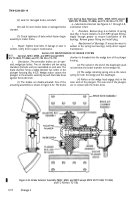

Test and Adjustment.

(1)

the ground.

(2)

(3)

and bottom

Jack up the semitrailer and lift all wheels off

Block the frame securely.

Release the fail-safe units (pars 2-4).

Remove dust plugs from access slots at top

of dust shield (fig. 4-59).

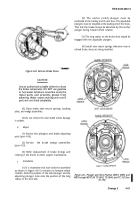

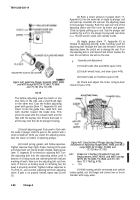

Figure

4-59.

Adjusting Brake Lining-to-Drum Clearance.

(4) Insert a feeler gage into the access slots and

check brake drum to brake lining clearance. If clearance is

between .040- and .060-inch, automatic adjusters are

operating and brakes are properly adjusted. If clearance is

not between .040- and .060-inch, proceed to step (5).

NOTE

If adjusting bolt starwheel will not turn using

hand pressure, lightly tap the tool with a

hammer.

(5) Insert brake adjusting spoon or long thin

screwdriver into slot to meet the starwheel on the

adjusting bolt. The adjusting bolt has right hand threads.

Turn the starwheel counterclockwise to reduce brake

lining-to-drum clearance.

(6) Back off the starwheel until you get a very

slight drag on the drum. Check brake lining clearance

again (step (4)).

(7) Repeat steps (4) through (6) above for the

other shoe on brake.

(8) Repeat steps (1) through (6) for all brake

assemblies.

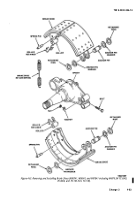

b.

Inspection and Replacement.

(1) Remove wheel

and drum assembly

(pars 4-49).

(2) Inspect brake linings for damage and wear.

New lining has approximately ½-inch of stock above

center rivets and approximately ¼-inch of stock above end

rivets. Replace brake shoe if lining is damaged or is worn

within .030-inch of rivet heads. By recording lining wear

between scheduled annual brake maintenance periods,

expected wear can be calculated. Shoes with linings that

will not last until the next scheduled maintenance internal

should be replaced.

c.

Removal.

(1) Remove hub, drum, and wheels (para 4-49).

(2) Turn the automatic adjusters with a brake

adjusting spoon or a long thin screwdriver clockwise until

the wedge brake plungers are fully contracted.

(3) Remove brake shoe return springs using

brake spring pliers.

(a)

Unhook top hook of both return springs.

(b)

Remove springs.

(4)

Remove brake shoes being careful not to

disturb the position of the wedge brake parts.

4-80

Change 3

Back to Top