TM-9-2330-356-14

SEMITRAILER, TANK: 5000 GALLON, BULK HAUL, SELF LOAD/UNLOAD M967 AND M967A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, AUTOMOTIVE M969 AND M969A1; SEMITRAILER, TANK: 5000 GALLON, FUEL DISPENSING, UNDER/OVERWING AIRCRAFT M970 AND M970A1

TECHNICAL MANUAL; OPERATOR’S, UNIT, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

OCTOBER 1990

TM-9-2330-356-14 - Page 221 of 528

TM 9-2330-356-14

c.

Repair. No repair is authorized. If damage is

found, replace the wedge assembly.

d.

Installation.

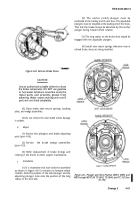

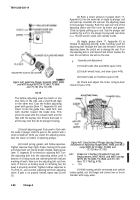

(1) Wipe plunger housing and wedge assembly

with clean rag.

(2) Install wedge assembly into the plunger

housing. It maybe necessary to turn wedge assembly to

engage the tabs (fig. 4-65) in the plunger housing. Check

for correct roller-plunger engagement by:

(a)

Observing that the ears on the roller

retaining cage are in corresponding slots in wedge bore of

plunger housing.

(b)

Pushing on wedge rod by hand while

checking for plunger and brake shoe lift.

d.

(c)

When properly installed, the wedge rod

standout is 2¼-inches from plunger housing. Measure the

standout of the wedge rod from the end of the threaded

plunger housing bore.

(3) Install brake chamber (paras 4-37 and 4-39).

Figure 4-65. Brake Wedge Alinement Tabs in Plunger

Housing (M967, M969, and M970 except M970

SN TC-0843, TC-0844, andTC-103thruTC-178).

4-36.

Brake Plungers and Brake Adjusting Parts,

M967, M969, and M970 except M970 SN TC-0843,

TC0844, and TC-103 thru T-178.

a.

Service. The

plungers and adjusting parts should

be serviced by following procedures c through e below

whenever the shoes have been removed.

b.

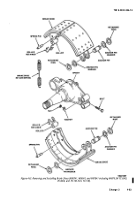

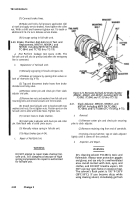

Removal of Adjusting Plunger Assembly.

(1) Remove brake shoe assemblies (para 4-33).

(2) Remove brake chamber(s) (paras 4-37 and

4-39).

(3) Remove hollow capscrew, gasket, and pawl

spring from side of plunger housing (fig. 4-66). If the pawl

does not come out with spring, use a small magnet to

remove the pawl.

(4) Pry the plunger seal loose. Remove the

adjusting bolt, seal, and adjusting sleeve as an assembly.

Remove the adjusting plunger.

c.

Removal of Anchor (Solid) Plunger.

(1) Remove the guide screw and gasket from side

of plunger housing (fig. 4-66).

(2) Remove plunger and seal assembly.

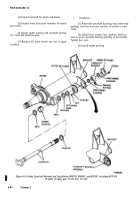

Inspection and Repair.

WARNING

Dry cleaning solvent P-D-680 Is toxic and

flammable.

Always wear protective

goggles and gloves, and use only In a

well-ventilated area. Avoid contact with

skin, eyes, and clothes, and DO NOT

breathe vapors. DO NOT use near open

flame or excessive heat. The solvent’s

flash point is 100°F-138°F (38°C-59°C).

If you become dizzy while using cleaning

solvent, Immediately get fresh air and

medical help. If solvent contacts eyes,

immediately wash your eyes with water

and get medical aid.

Compressed air used for drying or

cleaning purposes must not exceed 30 psi

(207 kPa).

Wear protective clothing

(goggles and gloves) and use caution to

avoid injury to personnel.

(1) Thoroughly clean all metal parts with dry

cleaning solvent (item 11, Appendix E). Dry the parts with

low pressure compressed air.

CAUTION

DO NOT use dry cleaning solvent to clean any

rubber parts. Damage to parts would result.

(2) Thoroughly clean plunger seals and gaskets

with mild soap solution and dry with low pressure

compressed air. Use wire brush on plunger parts and

adjusting bolt threads, if required, to remove caked on dirt

and corrosion.

Change 3

4-85

Back to Top