What is NSN?

National Stock Number

The Federal Stock Number (FSN) was an 11-Digit Numeric Code developed by the US Department of Defense in 1949 to identify items in the Army-Navy Catalog System. In 1974, the FSN was replaced with the National Stock Number (NSN) by simply adding two digits to the 11-Digit Code in positions 5 and 6 to signify the country of origin of the Numeric Code. In the instance of the USA, this code was 00. This enabled NATO Members to adopt the coding system while maintaining track of the NSNs created by that member.

NATO Stock Number

As the coding system has been adopted by the member nations of NATO, and other non-member nations as well, the system has come to be known as the NATO Stock Number, although the term National Stock Number has stuck in the USA. Now, both National Stock Number and NATO Stock Number are interchangeable terms for the same Codification System.

How Is It Used?

A NATO Stock Number is simply the official label applied to an item of supply that is repeatedly procured, stocked, stored, issued, and used throughout the NATO supply system. It is a unique, item identifying, series of numbers. When a NSN is assigned to an item of supply, data is assembled to describe the item. some data elements include information such as an item name, manufacturer's reference number, unit price, and physical and performance characteristics. Many data elements are stored in multiple languages and measurement systems. NSNs are an essential part of the military logistics supply chain used in managing, moving, storing, and disposing of material.

NSNs are used to identify and manage almost every imaginable item from aircraft parts to toilet paper, from space vehicles to nuts and bolts. The use of NSNs facilitates the standardization of item names, supply language, characteristics and management data and aids in reducing duplicate items in Government inventories. It also helps to standardize the military requirements for testing and evaluation of potential items of supply, as well as identifying potential duplicate items. The online USA NSN Search system is called WebFLIS.

National Stock Number

The NSN is officially recognized by the United States Government, the North Atlantic Treaty Organization (NATO) and many other Governments around the world. Government Agencies, including the US Department of Defense (DOD) and NATO, use the NSN to buy and manage billions of dollars worth of supplies annually. Currently, there are over 17 Million Active NSNs in the NSN Catalog and more than 10 Million Historical NSNs that are no longer actively used. Together, these NSNs represent more than 42 Million Manufacturer's Part Numbers from more than 2.6 Million Suppliers.

USA Federal Agencies

Many federal agencies, including the Department of Defense (DOD), use the NSN to buy and manage billions of dollars worth of supplies yearly. The Defense Logistics Agency (DLA) establishes how each DLA-managed NSN will be stocked, stored and issued to the military services. DLA evaluates usage demands to determine required quantities of NSNs. The NSN List is the foundation for logistics coordination between the services and government agencies.

Military Services

The practice of using a single language of supply like the NSN is increasingly important as it promotes coordination between the military services, readiness, and availability to all users. The NSN is also critical to the effective integration of the services in joint military endeavors. The NSN enables military services to access the same information and identify like items of supply. Mechanics, technical inspectors, maintenance and other supply personnel can review NSN data to locate information on all parts needed to maintain and support operations.

The use of NSNs provides logistics managers, procurement personnel, operations planners, and industrial base assessment personnel with a standard method of identifying and tracking items of supply in-storage, in-process, in-transit and in-theater.

Defense Reutilization

The Government Disposition Services identify products for reutilization and/or disposal using the NSN Database to distinguish what items require special handling upon disposal. Examples include items with specific demilitarization requirements, items containing precious metals, hazardous materials or sensitive and classified technology.

* Example of NSN

| Country | Active NSN | Non-Active NSN |

|---|---|---|

| USA | 6,829,952 | 9,056,531 |

| NATO | 1 | 14 |

| Germany | 1,297,623 | 109,443 |

| Belgium | 112,614 | 532 |

| France | 2,761,746 | 106,539 |

| Italy | 1,382,216 | 10,604 |

| Czech Republic | 26,814 | 90 |

| Netherlands | 288,775 | 680 |

| Brazil | 28,297 | 28 |

| Canada | 534,815 | 304,410 |

| Denmark | 158,337 | 100,633 |

| Greece | 41,942 | 63 |

| Iceland | 253,690 | |

| Norway | 0 | 108,789 |

| Portugal | 6,554 | 5 |

| Turkey | 398,381 | 1 |

| Singapore | 33,906 | 1 |

| Spain | 234,372 | 2,114 |

| Republic of Korea | 48,338 | |

| Estonia | 6,560 | 20 |

| Romania | 8,028 | 1 |

| Slovakia | 7,099 | 0 |

| Austria | 7,688 | 2 |

| Slovenia | 124 | 0 |

| Poland | 4,286 | 0 |

| Lithuania | 6,932 | 67 |

| Fiji | 17 | 0 |

| Tonga | 16 | 0 |

| Bulgaria | 8,666 | 7 |

| Hungary | 6,083 | 0 |

| Croatia | 368 | 0 |

| Latvia | 1,124 | 0 |

| Finland | 16 | 0 |

| Morocco | 9 | 0 |

| Australia | 310,075 | 6,565 |

| New Zealand | 108,198 | 40,061 |

| United Kingdom | 2,501,555 | 341,795 |

During World War II, it was common to find different names applied to a single item of supply used by each military service. That made it difficult for the military services to locate supplies and almost impossible to share items of supply. This resulted in an item shortage situation for one service and item surplus situation for another due to different naming conventions. To illustrate this complex issue, one only needs to consider what the name of a plain washer should be. Is it a washer, a spacer or a shim? All of these terminologies are correct, but the standardized name is WASHER,FLAT.

This is an example of why it is so important to establish a common name and description for a single item of supply. If each of the military services called this washer by a different name, there would be no way to identify and move assets from one service to another when needed. Additionally, it was determined to be essential that the DOD describe all like items the same, with the same characteristics to facilitate comparison of items and avoid proliferation of like items in the DOD inventory. Recently, it has enabled inventory sharing and standardization of items between militaries of different countries as well as between each of their military services.

Today, commercial entities continue to justify and reinforce the need for a standardized national stock numbering system. Manufacturers, as in the case of the preceding washer, use a variety of item names for identical parts. Cataloging these items with different item names creates inconsistencies in the various logistics management systems, making it difficult to identify, separate and control inventory of items.

Manufacturers use many different commercial part numbering conventions. For example, manufacturers may refer to their items of supply using various descriptors like a Universal Product Code (UPC), International Article Number (EAN), a National Drug Code, and or a Universal Standard Products and Services Classification Code (UNSPSC) as part of the item description. The NSN alleviates manufacturers from using various languages to describe items of supply by standardizing naming conventions and logistics management data.

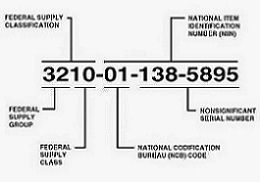

A NSN is formatted to convey specific information about the item of supply. The NSN is a 13-digit code and it is depicted as: 6240-00-357-7976. The first four digits of the NSN are known as the Federal Supply Class (FSC). For example, 6240 is the FSC for electric lamps. It is used to group like items, which would include fluorescent lamps, incandescent lamps, mercury lamps, and sodium lamps. The next two digits make up the Country of Origin code. This code signifies the country that originally requested the NSN assignment. Codes 00 and 01 are both used to identify the United States. The remaining seven digits are sequentially assigned and are unique to each NSN.

Manufacturers and suppliers do not have the authority to request a NSN. This is usually accomplished once a requirement/need for that manufacturer's/supplier's item has been identified by a military service, NATO country, federal/civil agency or various Contractor Support Weapons Systems (CSWS) managed by a contractor. Requests are then forwarded through the appropriate supply chain for cataloging and then forwarded to DLA Logistics Information Service for NSN assignment.

USA Users

For users in the USA, the DLA Logistics Information Service, located in Battle Creek, Michigan, assigns all NSNs at the request of the military services and certain federal and civil agencies. Each NSN assigned to an item of supply is the result of a careful review process known as cataloging. Cataloging is the process whereby each item of supply is named, assigned a Federal Supply Class, described to identify all known characteristics and performance data, and ultimately assigned a NSN. This information is contained and maintained in the Federal Logistics Information System (FLIS), which is managed by the DLA Logistics Information Service, which is part of the Defense Logistics Agency (DLA). DLA Logistics Information Service is the only organization authorized to assign NSNs. Requests for NSNs are initiated whenever a non-stocked item is repeatedly ordered or when a new weapons system is being developed. Whenever a new weapon system is deployed by a military service, the service engages in an upfront review known as a provisioning process. This process identifies all potential spares to ensure weapon system support throughout the life cycle of the weapon system. This step is essential to properly provide support to the warfighter. During the provisioning process all potential spare parts are identified and requests for NSN assignment are submitted to DLA Logistics Information Service. During NSN assignment, a wide range of logistics data is assembled to describe the item. This information includes the item name, manufacturer's part number, unit price, physical and performance characteristics, shipping data, special handling, storage, shelf life, and information associated with how to dispose of the item when no longer needed in the inventory. Throughout the life of the NSN, this data is routinely updated to include new manufacturers, price changes, part number changes or other changes affecting the support, logistics data, or characteristics of the item.

NATO Codification

Outside of the USA, certain participating member countries use the USA DLA Logistics Information Service under contract to issue and maintain their country-specific stock numbers and logistics information. Other member countries maintain their own codification bureaus that coordinate with NATO Central Command, NSPA, who in turn coordinate with the USA DLA Logistics Information Service. Examples of countries with their own codification bureau are: United Kingdom, France, Australia, Germany and Italy.

Non-NATO Codification

There is an increasing number of countries who are not members of NATO adopting the NATO Stock Number system for codification of supplies within their own Governments. NATO recognizes these countries by allocating a NATO Codification Bureaux (NCB) code for each new nation to use exclusively. This has the effect of enabling every country to adopt this common system and the effect has taken a wide hold. Examples of non-NATO collaborating nations include Singapore, Republic of Korea (South Korea) and Brazil.

- Reduces downtime by enabling procurement personnel to quickly identify, locate, and order parts or supplies

- Accounts for existing inventory

- Identifies shelf life of an item of supply

- Maximizes use of available spares by identifying items of supply that are interchangeable or substitutable

- Provides pricing information, which is valuable when negotiating contracts and managing military budgets

- Improves cycle times for design, manufacture, and repair processes while extending weapon system life cycles

- Centralizes item information on all items managed

- Provides built-in protection for safeguarding proprietary information and limiting access to only those entities requiring such information

- Records multiple manufacturers on NSNs which increases supportability

- Aids in identifying duplicate items of supply

Perhaps the most significant and far-reaching benefit of the NSN is that it provides life cycle management of items of supply, from requisition to acquisition to maintenance to disposal.

The Bottom Line

The NATO Logistics Information Service (FLIS/MCRL/NMCRL) is used worldwide for logistics information and the National Stock Number (NSN) is the international language of Governmental logistics. Together, the NATO Logistics Information Service and the NSN make sense of the ever expanding array of suppliers and supply parts, and provides affordable readiness and reduction of total ownership cost.

Back to TopBack to Top