TM-55-1425-289-14

TM-55-1425-289-14 - Page 51 of 61

TM 55-1425-289-14

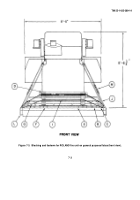

Table 7-1.

Application of Materials for Loading and

Securing ROLAND Fire Unit (Figs 7-2, 7-3, 7-4, and

7-5)

Item

No. Required

Application

A

4

Support assembly.

See the "support assem-

bly detail in figure 7-4.

Nail the assembly

to the car floor with four 16d nails.

B

4

Pallet beam stiffeners, 2- x 6- x 48-inch

(doubled).

Position so that it is approximate-

ly 2 inches from contacting the lateral

stiffener on the underside of the pallet.

Nail

the first piece to the car floor with seven 20d

nails.

Nail the second piece to the first with

seven 50d nails.

C

8 each

Side blocks, 2- x 6- x 42-inch and 2- x 8- x

42-inch.

Position the first 2- x 6-inch piece

next to the pallet, and nail to the car floor

with eleven 20d nails.

Position the second 2-

x 6-inch piece on top of the first piece

(against pallet beam web), and nail the

eleven 20d nails.

Nail the second 2- x 8-inch

piece to the first in a like manner.

D

2

Knee brace assembly.

See the "knee brace as-

sembly" detail in figure 7-4.

Position as

shown, on top of the pallet transverse beam,

centered on the fire-unit module hull.

E

2

Headers, 2-inch x 6-inch x 7-ft 0-inch

(doubled).

Nail the first piece to the car floor

with sixteen 20d nails.

Nail the second piece

to the first with sixteen 50d nails.

F

8

Backup cleats, 2- x 6- x 36-inch (doubled).

Position two cleats side by side to align with

piece marked D, as shown in figure.

Nail the

first piece to the car floor with nine 20d

nails.

Nail the second piece to the first with

nine 50d nails.

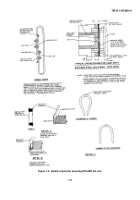

G

4

Dunnage holddown straps, 2-inch x .050-

inch by length-to-suit.

Install to form a com-

plete loop over the knee brace assembly.

Thread through the stake pocket from inside

to outside on each side of the car and bring

both ends up above the knee brace assembly,

where they can be tensioned and sealed with

two seals.

Secure to the knee brace assembly

with the two 20d nails driven partially into

the assembly and bent over the strap at each

end of the assembly.

H

8

Pads, steel, strapping, 2-inch x .050-inch

long.

Position pad under stake pocket, and

seal to holddown strap marked G (fig 7-5,

detail A).

For alternate stake pocket protec-

tor (16 required), use two pads under each

stake pocket with a holddown strap (see fig

7-5, detail A).

I

16

Seals, 2-inch strapping, four per strap.

Double-crimp each seal except those used to

secure the pads marked H.

J

2

Wire rope, steel, 112-inch-diameter, 11.5-

ton.

Form a complete loop through a car

stake pocket and around the tiedown facility

at the forward end of the lading.

K

1

Wire rope, steel, 112-inch dia, 11.5-ton.

Form a complete loop through the car stake

pockets and the aft end of the cable facilities

as shown in figure 7-5.

Table 7-1.

Continued

Item

No. Required

Application

L

6

Thimble, standard, 1/2-inch.

Use one each

for the car stake pocket and the forward end

tiedown facility.

Secure to cables marked J

and K with one clip per thimble.

Note: A

standard thimble as specified can be secured

to a cable with a 11/2-inch clip.

However, if

desired, or if the 1/2-inch thimble being used

is of a type that cannot be secured to a cable

with a 112-inch clip, a 5/8-inch clip may be

used.

Alternate: No.

14 gauge wire may be

used.

M

18

Clip, wire rope, 1/2-inch.

Use four per cable

joint of pieces marked J and K and one per

thimble.

N

as required

Waterproof paper or burlap.

Position paper

or burlap between cable and lading at points

of contact.

Tape or wire tie to prevent dis-

placement.

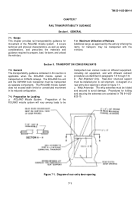

7-6.

Loading of XM1058 Truck transporter on

General Purpose Flatcar

a.

The vehicle may be placed in the tiedown

position on the flatcar by crane.

It may be driven or

towed into position if a suitable ramp or bridge is

available.

The application of materials for loading and

securing the XM1058 truck transporter is shown in table

7-2.

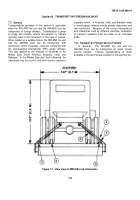

Figure 7-5 shows an isometric view of the truck

transporter, and figure 7-6 shows a rear view of the truck

transporter.

b.

When the vehicle is loaded and tied down, the

handbrakes must be set.

The transmission gearshift

must be in neutral.

c.

Fire Unit slinging and railcar loading details are

shown in figures 6-2 and 7-8, respectively.

Blocking

details for lading are presented in figure 7-9.

Table 7-2.

Application of Materials for Loading and

Securing XM1058 Truck Transporter (Figs 7-5

Through 7-6)

Item

No. Required

Application

A

8

Wheel blocks.

Place the 450 end of block

against a wheel.

Nail through heel of block

with three 40d and two 60d nails.

Toenail

each side to car floor with two 40d nails.

B

2

Rubbing strips, 2-inch x 6-inch x 7-foot 6-

inch.

Position on edge of wheel block, and

nail to lower piece marked C with one 12d

nail every 8 inches.

C

2

Side blocks, 2-inch x 4-inch x 7-foot 6-inch

(tripled).

Nail the first piece to the car floor

with one 30d nail every 8 inches.

Nail each

additional piece in a like manner.

D

2

Rubbing strips, 2- x- x 36-inch.

Position on

edge of side block, and nail to lower piece

marked E with five 12d nails.

E

2

Side blocks, 2- x 6- x 36-inch (tripled).

Nail

the first piece to the car floor with five 30d

nails.

Nail each additional piece in a like

manner.

7-6

Back to Top