LO-5-3805-254-12 - Page 7 of 8

NOTES:

1.

ARMY OIL ANALYSIS PROGRAM (AOAP).

For Active Army units, obtain samples from engine

and automatic transmission every 500 miles

(805 km) of operation or 60 days (whichever comes

first). Reserve and National Guard activities will use

500 miles (805 km) or 120 days as the prescribed

sample intervals. Reserve and National Guard

equipment in frequent use during active training

period will adhere to the schedule for Active Army

units. As a minimum, one sample from each item of

equipment will be submitted for each units’ two

week active training period. Send these samples to

the nearest AOAP laboratory. Refer to TB 43-0210 for

sampling instructions. When or if AOAP laboratory

support is unavailable, hard time intervals will apply.

NOTE

l

Do not hold ON samples. Submit oil

samples as soon as they have been taken.

l

Seasonal oil changes will be made due to

expected temperatures (see Key).

2.

FOR OPERATlON OF EQUIPMENT IN

PROTRACTED COLD TEMPERATURES BELOW

-10°F (-23%).

Remove lubricants prescribed in

Key for temperatures above -10°F (-23%).

Relubricate with lubricants specified in Key for

temperatures below -10°F (-23%). If OEA lubricant

is required to meet the temperature ranges

prescribed in the Key, OEA lubricant is to be used in

place of OE/HDO-10 lubricant for all temperature

ranges where OE/HDO-10 Is specified in the Key.

3.

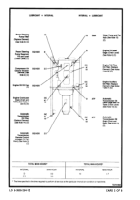

OIL CAN POINTS.

Each 2500 miles

(4023 km), lubricate transmission remote control

linkage, pivot pins, sliding surfaces, accelerator

linkage, door hinge pins, cab latch, pedal-to-brake

valve linkage, butterfly-type hood hinge, and all

exposed adjusting threads with OE/HDO-10.

NOTE

When OEA oil is used, oil level should be

checked more often.

4.

ENGINE OIL LEVEL HOT OR COLD CHECK.

Cold engine, oil level should be at “H” (high) mark

on dipstick. Hot engine, oil level must be between

“H” (high) and “L” (low) marks on dipstick (allow to

set five minutes before checking).

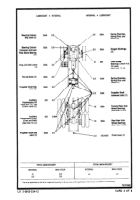

5.

ENGINE CRANKCASE.

Oil is to be changed

each time an engine oil change is directed by AOAP

laboratory. When AOAP laboratory support is not

available, change oil every 1000 miles (1609 km).

Drain when lubricant is warm.

6.

ENGINE FULL FLOW OIL FILTER.

Filter

element is to be replaced each time an engine oil

change is directed by AOAP laboratory. After

installing new filter element, fill crankcase, operate

engine for five minutes, check housing for leaks,

check crankcase oil level, and bring to “H” (high)

mark on dipstick. When AOAP support is not

available, install new filter element each 1000 miles

(1609 km).

7.

ENGINE AUXILIARY OIL FILTER.

Filter

element is to be replaced each time an engine oil

change is directed by AOAP laboratory. After

installing new filter element, fill crankcase, start

engine, and loosen vent plug in cover. Tighten vent

plug when oil appears at plug. Operate engine for

five minutes, check housing for leaks, check

crankcase oil level, and bring to “H” (high) mark on

dipstick. When AOAP laboratory support is not

available, install new filter element each 1000 miles

(1609 km).

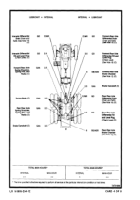

8.

POWER STEERING PUMP FILTER.

Each

10,000 miles (16,090 km), drain power steering

reservoir, remove cover plate, filter element, and

clean inside of reservoir with lint-free cloth. Install

new filter element and replace cover. Fill reservoir to

indicated level or 1½ in. (3.8 cm) below top of filler

neck on reservoir. With engine running, turn wheels

from left to right and continue filling until the proper

level is maintained. When operating in dusty areas,

replace filter element more often.

9.

AIR

CLEANER

STRAINER

(AIR

COMPRESSOR).

Each 2500 miles (4023 km),

remove strainer from air cleaner. Clean strainer, oil

lightly with OE/HDO-30, and install in air cleaner.

When operating under extreme dusty conditions,

service strainer more often.

10.

WATER PUMP AND FAN HUB.

Each 10,000

miles (16,090 km), remove pipe plugs, install

fittings, lubricate with a shot (tablespoon full) of

GAA, and install pipe plugs.

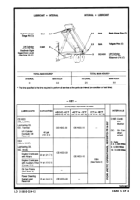

11.

FORWARD-REAR AND REAR-REAR AXLE

WHEEL BEARINGS.

Each 10,000 miles

(16,090 km), remove wheels, clean and inspect all

parts, and replace damaged or worn parts. Repack

bearings, assemble, and adjust bearings.

12.

FORWARD-REAR AND REAR-REAR AXLE

BRAKE CHAMBER.

Each 5000 miles (8045 km),

add 2 oz (59 cc) of OE/HDO-10 through air inlet port

at each brake chamber to lubricate seal.

TA701869

LO 5-3805-254-12

CARD 7 OF 8

Back to Top