LO-5-3895-372-12 - Page 7 of 9

NOTES

1. FOR

OPERATION

OF

EQUIPMENT

IN

PROTRACTED COLD TEMPERATURES BELOW -

150F (-260C).

Remove lubricants prescribed in Key for

temperatures above -15OF (-260C).

Relubricate with

lubricants specified in Key for temperatures below -150F

(-260C). If OEA lubricant is required to meet the

temperature ranges prescribed in the Key, OEA lubricant

is to be used in place of OE/HDO-10 lubricant for all

temperature ranges where OE/HDO-10 is specified in

the Key.

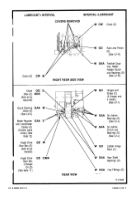

2. OIL CAN POINTS.

Each day lubricate winch pulleys

with OE/HDO and swivel rings with GO.

Each week

lubricate quick acting valves, cement lid clamps, fluffer

valve, conveyor belt tensioning devices with OE/HDO

and hinges, ladder hinge point, rack and pinion, and

slides with GO.

3. WINCH

CABLES.

Semiannually, unwind entire

cable, clean and oil.

Using a brush soak with OE/HDO.

Wipe off excess and coat with CW before rewinding

cable on drum.

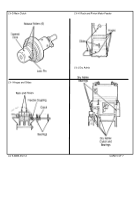

4. CEMENT BIN BEARINGS.

To avoid getting grease

in cement bin, do not overlubricate.

5. AUGER BEARING.

Lubricate while auger is turning.

Flush with grease every 4 hours during operation, and at

every cleanup. This bearing cannot be greased too often

or too much.

6. MAIN CLUTCH.

Apply several drops of OE/HDO oil

on the lock pin and release rollers through the 6 holes in

the clutch cover. Oil the tapered cone.

7. HYDRAULIC FILTER.

After initial 6 month change,

each 2 years remove element, clean filter shell, and

install new element.

After replacement, operate for 5

minutes, check for leaks, check level and bring to full

mark.

8.

POWER TRAIN UNIVERSAL JOINTS.

Each

week turn prop shaft by hand to gain access to lub

fittings. Do not JOINITS.

Each week turn prop shaft by

hand to gain access to lub fittings.

Do not

overlubricate. Excess grease will burst seals.

9.

AIR LUBRICATOR.

Each day check oil in sight

glass.

If oil is not visible remove bowl and fill with

OE/HDO.

10.

METER

REGISTER

AND

TACHOMETER

CABLES. Each 6 months remove cables from meter

register and tachometer ends, lubricate with GAA and

reinstall.

11.

ANGLE DRIVE GEAR BOX.

Check level each

week.

Change gear lubricant only when

required

by

maintenance repair action, contamination by water or

other foreign material.

After refill, operate for 5 minutes,

check for leaks and bring oil to full mark.

12.

LUBRICANTS. The following is a list of lubricants

with military symbols and applicable specification

numbers.

OE/HDO

MIL-L-2104

GO

MIL-L-2105

GAA

MIL-G-10924

OEA

M IL-L-46167

CW

VV-L-751 D

(SD), Type II

P-D-680

Copy of this Lubrication Order will remain with the

equipment at all times, instructions contained herein are

mandatory.

By order of the Secretary of the Army:

JOHN A. WICKHAM, JR.

General, United States Army

Chief of Staff

OFFICIAL:

ROBERT M.

JOYCE

Major General, United States Army

The Adjutant General

DISTRIBUTION:

To be distributed in accordance with DA

Form

12-25B,

Operator

and

Organizational maintenance requirements

for Concrete Mixers.

LO 5-3895-372-12

*U.S. GOVERNMENT PRINTING OFFICE: 1994 0-300-721(00320)

CARD 7 OF 7

Back to Top