LO-9-2320-363-12 - Page 23 of 24

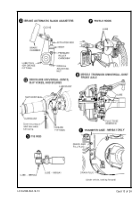

9. PINTLE HOOK (M915A2/M916A1)

Lubricate all fittings every 5,000 miles or semiannually with GAA. Clean and lube other parts with

an authorized solvent and OE/H DO.

10.

11.

12.

13.

14.

15,

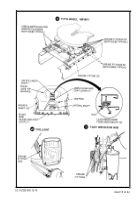

FIFTH WHEEL (M915A2/M916A1)

Every 5,000 miles or weekly apply GAA to top plate and latch and all lubrication fittings. Clean

and lube moving parts on underside with authorized solvent and OE/HDO and grease top plate

and latch as required.

WINCH (M916A1)

a. Hydraulic Reservoir - Check level prior to operating winch. Change oil any time the oil becomes

contaminated with water (milky appearance) or metallic particles due to circuit component failure.

Remove and clean or replace inlet strainer and replace return filter element in conjunction with

fluid change. If oil is found not contaminated during required interval inspection because winch

was not used, retain oil but replace filter.

b. Hydraulic oil must be sampled every 90 days as prescribed by DA Pam 738-750.

WINCH DRUM (M916A1)

Check and fill semiannually. After initial 5,000 miles of vehicle operation, drain and fill winch drum;

thereafter drain and fill annually.

WINCH CABLE (M916A1)

Unwind entire cable, clean and oil every 5,000 miles or semiannually. Using a brush, soak cable

with clean OE/HDO. Wipe off excess and coat with GAA before rewinding cable on drum. Examine

cable after each use. Clean and lubricate as necessary.

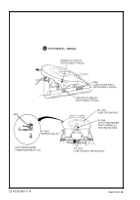

ARMY OIL ANALYSIS PROGRAM (AOAP) SAMPLING PROCEDURES

The engine oil sampling valve is located on the transmission oil cooler bracket, beside the engine

oil dipstick (view A). The transmission oil sampling valve is next to the transmission oil dipstick,

just under the exhaust pipe (view Y). The hydraulic winch oil sampling valve is located on the winch

filter housing (view Z).

a.

b.

c.

d.

Ensure that the oil to be sampled is at its normal operating temperature (TM 9-2320-363-10).

Open valve, pump approximately 2 ounces (60 ml) into a suitable container, and discard. This

will remove waste impurities.

Place sample bottle (TB 43-0210) under valve and fill sample bottle to approximately 1/2 inch

(1.3 cm) below neck of bottle. Close valve and check for leaks.

Send oil sample to AOAP Iaboratory. If AOAP laboratory is not available, use hard time intervals.

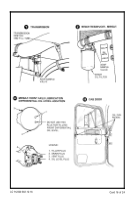

OIL CAN POINTS

Every 5,000 miles lubricate these points using OE/HDO sparingly:

a. Door hinges and latches (view BB).

b. Driver and passenger seat adjusters and sliding tracks (view CC).

c. Spare tire carrier (M915A2 and M916A1) ratchet gear shaft (view DD).

Card 23 of 24

LO 9-2320-363-12-23

Back to Top