LO-9-2320-386-12 - Page 2 of 20

LO 9-2320-386-12

Corrosion Prevention and Control (CPC).

Corrosion prevention and control (CPC) of Army

materiel is a continuing concern. It is important that

corrosion problems are reported so they can be

corrected and improvements can be made to prevent

future problems.

While corrosion is typically associated with rusting of

metals, it can also include deterioration of other

materials, such as rubber and plastic. Unusual

cracking, softening, swelling, or breaking of these

materials may be a corrosion problem.

If a corrosion problem is identified, it can be reported

using Standard Form 368, Product Quality Deficiency

Report. Use of key words such as corrosion, rust,

deterioration, or cracking will ensure that the

information is identified as a CPC problem.

The form should be submitted to the address specified

in DA PAM 738-750.

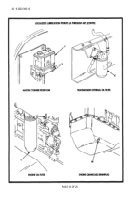

Oil Filters.

Oil filters shall be serviced/cleaned/

changed/ as applicable, when:

1. They are known to be contaminated or

clogged;

2. Service is recommended by AOAP

laboratory analysis, or

3. Prescribed hard-time intervals are

reached.

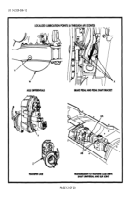

AOAP Requirements.

Sample oil from all oil-wet

components every 60 days or 1,000 miles (1,609

km). Reserve and National Guard units should

perform oil sampling every 120 days or 1,000 miles

(1,609 km). In the event AOAP laboratory support is

not available, on-condition (OC) hard-time intervals

may be applied.

l

Drycleaning solvent is flammable and will

not be used near open flame. Use only in

well-ventilated places. Failure to do so

may result in injury to personnel.

l

and

Keep all lubricants in a closed container

store in a clean, dry place, away

from extreme heat. Failure to do so may

result in injury to personnel.

CAUTION

Keep container covers clean and allow no dust, dirt,

or other foreign material to mix with lubricants. Keep,

all lubrication equipment clean and ready to use.

NOTE

Man hours have not been established.

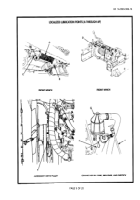

Cleaning.

Keep all external parts of equipment not

requiring lubrication free of lubricants. Before

lubricating equipment, clean fittings. Use drycleaning

solvent, Type II (SD-2) (P-D-680) biodegradable, to

wipe all lubrication points free of dirt and grease. Dry

before lubricating. After servicing lubrication points,

wipe off excess lubricants to prevent accumulation of

foreign matter.

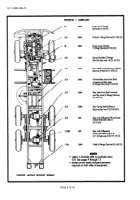

Table I. Interval and Lubrication Key.

The following is a list of service intervals, abbrevia-

tions, and keys, appearing in this LO.

OE/HDO

Lubricating oil,

combustion engine,

tactical (Mll-L-2104)

Go

Lubricating oil, gear, multi-

purpose (MIL-L-2105)

BFS

Brake fluid, silicone

(MIL-B-46176)

GAA

Grease, automotive and

artillery (MIL-G-10924)

Lubricating oil, internal

combustion engine, arctic

(MIL-L-46167)

CW

Lubricating oil, chain,

exposed gear, and

wire rope (VV-L-751)

PAGE 2 OF 20

Back to Top