LO-9-2350-266-12 - Page 35 of 48

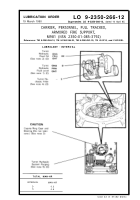

KEY

EXPECTED

TEMPERATUR E

LUBRICANTS/

CAPAC-

Above

+40° F

0°F to

INTERVALS

COMPONENT S

ITIES

+32° F

-65° F

(AP-

(Above

-10° F (-18° C

PROX)

0°C)

( + 5°C

-54°C )

-23°C )

GIA

GREASE,

As req

S - Semi-

MIL-G-23827)

INSTRUMENT,

annu-

AIRCRAFT

ALL

ally or

TEMPERATURES

GAA

Every

GREASE,

As req

1500

MIL-G-10924)

AUTOMOTIVE

AND

Miles

A - Annu-

ARTILLERY

ally

OE/HDO

Lubricat -

es req

MIL-L-2104D)

ING OIL,

OR

INTERNAL

OEA

COMBUSTION

MIL-L-46167)

ENGINE

# FOR ARCTIC OPERATION REFER TO FM 9-207

NOTES:

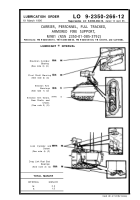

1.

TACHOMETER AND SPEEDOMETER SHAFTS. Annually, disconnect shafts at both ends (TM

9-2350-261-20), remove slotted washers from drive ends of cores, and remove cores from

instrument panel end of shafts. Clean and lubricate cores with GIA. Insert cores in shafts. Install

slotted washers and connect both ends of shafts. If tachometer adapter has a grease fitting,

lubricate sparingly with lubricant GIA.

2.

OIL CAN POINTS. Every 1500 miles, semiannually, or as required, lubricate ramp hinges;

ramp door hinges; power plant door hinges; trim vane hinges and latches; driver’s, commander’s

and cargo hatch hinges; control linkage pins and shafts; and seat control. Lubricate air box heater

air motor. Use OE/HDO or OEA, as appropriate.

3.

LUBRICATE AT TIME OF ASSEMBLY. Coat ends of suspension torsion bar, idler wheel

support arm spindle and bearings, steering control linkage bearing surfaces and pins, and towing

pintle shaft with GAA or GIA as specified during assembly procedure. Pack new support arm and

idler hub before assembling.

Card 40 of 51/(52 blank)

Back to Top