TB-9-2920-225-34-1 - Page 19 of 70

TB 9-2920-225-34-1

Table 2-4. Substitutes for D1-Model 03

If the regulator still does not function correctly

it will be necessary, if local skills permit, to test

each component. All the parts should be checked

with an ohmmeter and the capacitors checked with

a capacitance meter.

The circuit board traces

should be checked with an ohmmeter to make sure

that there are no cracked traces. Traces with hair-

line cracks will show good at lower temperatures

and will tend to show open circuit at higher tem-

peratures. If the board seems good at room tem-

perature, but the regulator still fails, this could

be the cause.

Section IV. VAP-AIR MODEL 26440001-04

2-8. General.

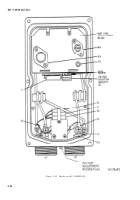

Figure 2-10 is a plan view of the

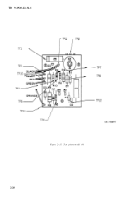

regulator with the cover off. Figure 2-11 is an

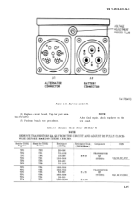

end view of the regulator showing the receptacles

and the voltage adjustment points. Figure 2–12 is

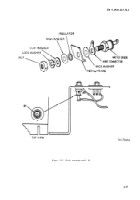

an exploded view of the diode mounting. Figure

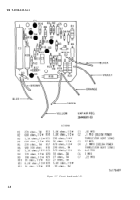

2–13 is a relay location. Figure 2–14 is a view of

the circuit board and transistor heat sink. Figure

2–15 is a view of the circuit board showing the

electrical test points. There are 12 electrical test

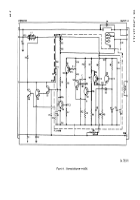

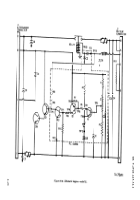

points. Figure 2–16 is an electrical schematic dia-

gram of the regulator. Table 2–5 lists the resist-

ance checks, and table 2-6 1ists the voltage checks.

Table 2–7 is a transistor substitution list.

2-9. Checkout and Repair.

a. Voltage Adjustment Rheostat (Rz) (Power

Disconnected).

(1) Place ohmmeter test probes to terminals

of the rheostat (see fig. 2-10).

(2) Rotate rheostat fully clockwise, reading

should be approximately 250 ohms.

(3) Rotate rheostat fully counterclockwise,

reading should be less than 5 ohms.

(4) If other readings are obtained, replace

rheostat.

b. Transistors.

(1) Remove transistors Q4 and Q5 (see fig.

2–l0).

(2) Position transistors as shown in figure

2-1, and check them separately (see fig. 2–2).

(3) If resistance values cliffer from the values

shown in figure 2–2, replace the transistors

through cannibalization or requisition transistor

Q4, Vap-Air part number 26316033-12 (2N3441),

NSN 5961–00–054–4141, or transistor Q5, Vap-

Air P N 26316033–70 (2N3773), NSN 5961–00–

929–5014 (see table 2–7 for substitutes).

(4) Check the mica insulating washers be-

tween the transistors and mounting plate. Replace

if cracked, broken or missing. Coat washers with

insulation compound per MIL–S–8660, NSN 6850–

00-880-7616.

c. Diode.

(1) Remove four screws holding transistor

and circiut board mounting plate, and move plate

to one side.

(2) Place negative ohmmeter probe to the

topside of diode D4 (see fig. 2-12).

(3) Place positive probe to the bottom of D4.

Meter should indicate low resistance.

(4) Reverse probes. Meter should indicate

high resistance.

(5) If other readings are obtained replace

diode D4 (MR1122), NSN 5961–00–103–1519 (see

fig. 2-12) .

d. Relay.

(1) Place ohmmeter probes across relay coil

terminals (see fig. 2-13).

(2) Place ohmmeter probes across terminals

(see fig. 2-13). Meter should read infinity (open

circuit).

(3) If other readings are obtained, replace

relay, NSN2920–00–735–9542.

(4) Reinstall transistor and circuit board

mounting plate.

e. Detailed Circuit Checks.

(1) Table 2–5 contains

“power off’’

resistance

checks of the circuit (see fig. 2–15 for test points).

(2) Table 2-6 contains

“power on”

voltage

checks of the circuit (see fig. 2–15 for test points).

f. Functional Check.

Check the performance of

the regulator on the test stand and make final volt-

age adjustments. Voltage output should read 28

volts. If the regulator does not function properly,

perform the following:

( 1 ) Check wires and connections.

2-13

Back to Top