TB-9-352 - Page 2 of 7

When loads are applied to the boom

cable, all personnel other than the

operator must retire to a safe distance.

Use only wire rope of sufficient

strength for the weight to be lifted.

CAUTION

When handling the test weights and

performing load-tests, do not exceed

the maximum weights for the various

boom radii specified on the safe-load

data plates located on the cover of the

control-valve bank in the operator’s

compartment.

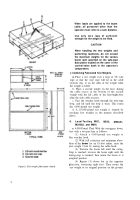

Figure1. Test-weight fabrication details

4.

Combining Fabricated Test Weights.

a.

Place a test weight over a loop of 5/8 wire

rope so that the wire rope will lie in the cable

recesses (fig. 1) on the sides of the weight when

the weight is lifted.

b. Place a second weight on the first, alining

the cable recess in the bottom of the second

weight with the lift cable of the firstweight.Also

aline the side cable recesses.

c. Pass the wrecker hook through the wire-rope

loop, and lift until the loop is tense. This forms

the 4,000-pound test weight.

d. A 10,000-pound test weight is formed by

stacking five weights in the manner described

above.

5.

Load-Testing M62,

M543,

M543A1,

M543A2, and M816.

a.

4,000-Pound

Test.

With the outriggers down,

test with a two-part line as follows:

(1) Attach a 4,000-pound test weight to

the wrecker hook.

(2) With full extension and minimum eleva-

tion of the

boom

for an 18-foot radius, raise the

test weight 2 feet by raising the cable hook.

(3) Traverse the boom left until the swing-

stop is reached; traverse the boom right until the

swing-stop is reached; then return the boom to it

original position.

(4) Repeat (3) above but in the opposite

direction, traversing right first. Then return the

test weight to its original position on the ground.

2

Back to Top