TM-1-1500-344-23-2 - Page 201 of 240

A-31

NAVAIR 01-1A-509-2

TM 1-1500-344-23-2

15 April 2009

A-11.

SCOPE

. This section discusses aircraft and

engine cleaning. For corrosion charts of the specific

aircraft, refer to the applicable maintenance instruction

manual (MIMs), or contact the Fleet Support Team

(FST) for the aircraft.

A-12. AIRCRAFT CLEANING.

Cleaning compounds

and materials which appear only in Appendix B

(Supplemental Requirements for Army Aircraft) are not

authorized for cleaning Navy aircraft. See Chapter 2 for

detailed information on aircraft cleaning procedures

and authorized materials and equipment.

A-13. EQUIPMENT FOR ENGINE CLEANING

.

A-13.1. JET ENGINE CORROSION CONTROL CART.

The corrosion control cart, P/N 65A102-J1-1, is designed

for cleaning and rinsing the compressor section of

turbine engines. It is a trailer mounted, self contained

mobile unit designed for shipboard use and shore

based operations (see Figure A-18). The cart consists

of a 33 gallon capacity solution tank and a work platform

area on top of the solution tank. There is a water supply

APPENDIX A

SUPPLEMENTAL REQUIREMENTS FOR NAVY AIRCRAFT

SECTION II. AIRCRAFT AND ENGINE CLEANING

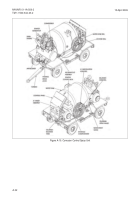

Figure A-18. Jet Engine Corrosion Control Cart

hose and applicator storage area on the right hand side.

Two air cylinders are mounted on the left hand side to

supply the air pressure needed to discharge the water

solution from the solution tank. The instruction plate and

schematic diagram are mounted on the left hand side to

provide information about operating the unit. The

33 gallon capacity solution tank is divided into two

separate compartments: a 7 gallon preservative

compartment at the front end of the unit and the 26 gallon

water compartment at the rear end of the unit. On top of

each compartment is a filler opening and at the bottom

of each compartment is a plug for drainage purposes.

The operational instructions of the cart are listed in

NAVAIR 19-20D-1 (Jet Engine Corrosion Control Cart).

Washing with MIL-PRF-85704 (Gas Path Cleaner) shall

be performed as follows:

a. Fill the 7 gallon forward tank with 1 gallon of

MIL-PRF-85704 Type II and 4 gallons of fresh water, or

with 5 gallons of MIL-PRF-85704 Type II RTU (ready

to use). Then fill the 26 gallon aft tank with fresh water.

b. Prepare the aircraft for turbine engine washing in

accordance with the applicable maintenance

requirements.

c. Spray the cleaning solution or fresh water as

required (see Table 2-1 for additional information).

A-13.2. CORROSION CONTROL SPRAY UNIT,

TRAILER

MOUNTED.

The

spray

unit,

P/N 76E04000-30A, stores and controls the delivery of

water, preservative oil, and cleaning solutions to the

compressor section of turbofan, turbojet, and turboshaft

engines. It is a self contained sprayer mounted on a

towable trailer (see Figure A-19). The spray unit consists

of a 200 gallon water tank and a 10 gallon oil/cleaning

solution tank. Compressed air from the compressor

assembly pressurizes the tanks for delivery of fluids.

The solution tank is a reservoir for storage of preservative

or cleaning solutions. Fresh water from the water tank

is usually used during corrosion control for rinsing. The

4:1 mixer assembly mixes four parts water to one part

chemical in the solution tank. The unit can also supply

compressed air directly to the aircraft being serviced.

The unit is secured to an aluminum chassis mounted on

a four wheel running gear. Operating instructions for

the unit are listed in NAVAIR 19-20D-2 (Corrosion

Control Spray Unit).

Back to Top