TM-5-2330-325-13-P - Page 408 of 648

Inspection - Continued

d.

Corrosion or other deterioration.

e.

Missing or damaged parts.

f.

Water in components.

g.

Any other readily recognizable shortcomings or deficiencies.

Repair During Administrative Storage

Keep equipment in an optimum state of readiness. Accomplish the required services and repairs as

expeditiously as possible. Whenever possible, perform all maintenance on-site.

Exercising

Exercise equipment with Table 1 and the following instructions:

a.

Vehicle Major Exercise.

Depreserve equipment by removing only that material restricting exercise.

Close all drains, remove blocks, and perform all BEFORE operational checks. Make several right and

left 90-degree turns. Make hard-braking stops without skidding. While exercising, and when it is

convenient and safe, operate all other functional components and perform all DURING and AFTER

operational checks.

b.

Scheduled Services.

Scheduled services will include inspection per

Inspection

in this WP, and will be

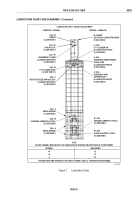

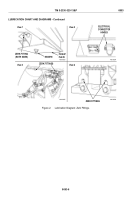

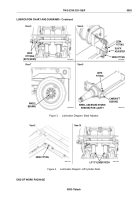

conducted in accordance with Field PMCS (WP 0034). Lubricate in accordance with instructions in

(WP 0093).

c.

Corrective Action.

Immediately take action to correct shortcomings and deficiencies noted. Record

inspection and exercise results on DA Form 2404/5988-E. Record and report all maintenance actions

on DA Form 2407. After exercising, restore the preservation to the original condition. Replenish

lubricants used during exercising and note the amount on DA Form 2408.

Table 1.

Exercise Schedule.

Weeks

2

4

6

8

10

12

14

16

18

20

22

24

Scheduled

Services

X

Major Exercise

X

Rotation

Rotate items with any rotational plan that will keep the equipment in an operational condition and reduce the

maintenance effort.

Procedures for Common Components and Miscellaneous Items

1.

Tires.

Visually inspect tires during each walk-around inspection. This inspection includes checking tires with

a tire gage. Inflate, repair, or replace as necessary those found to be low, damaged, or excessively worn.

Mark inflated and repaired tires with a crayon for checking at the next inspection.

2.

Seals.

Seals may develop leaks during storage or shortly thereafter. If leaking persists, refer to the

applicable maintenance section in this manual for corrective maintenance procedures.

TM 5-2330-325-13&P

0092

0092-4

Back to Top