TM-55-2350-262-14 - Page 14 of 42

CHAPTER

4

AIR TRANSPORTABILITY

TM

GUIDANCE

55-2350-262-14

4-1. Scope

This chapter provides air transportability guidance

for the movement of the M9 ACE vehicle. It covers

technical and physical characteristics, as well as

safety considerations,

and prescribes the man-

power, material, and time required to prepare,

load, and tie down the vehicle on, or unload the

vehicle from, U.S. Air Force aircraft.

4-2. Maximum Utilization of Aircraft

The loads described in this section are not maxi-

mum loads. General guidance on total cargo loads

and on operating ranges is provided in TM

38–236/AFP 71–8. Additional cargo and/or person-

nel within allowable load limits and restrictions

prescribed by pertinent safety regulations can be

transported.

4-3. Applicability

a.

U.S. Air Force Aircraft.

The M9 ACE is

transportable in C–130, C–141, and C–5 aircraft.

Procedures in this manual and those prescribed in

TO 1C-130A-9, TO 1C-141A-9, and TO 1C-5A-9

are applicable.

b. Tiedown.

This vehicle is tied down in ac-

cordance with the applicable TO 1C–XXX–9, sec-

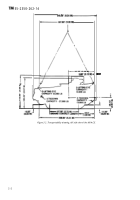

tion IV. Figures 4–1 through 4–3 show the sug-

gested tiedown patterns for the M9 ACE in the

C-130, C-141, and C-5 aircraft, respectively. Ta-

bles 4-1 through 4-3 show the suggested tiedown

patterns for the M9 ACE in the C-130, C-141, and

C-5 aircraft, respectively. Tables 4-1 through 4-3

list the tiedown devices required, the locations of

tiedown points, the corresponding fittings to which

the devices are secured, the number and capacity

of the devices, and the lumber shoring required for

loading and/or securement.

(1) The rolling shoring requirements listed

in tables 4–4 and 4–5 are to be applied in

sequence from the top to the bottom of the table,

with the first items for the ground, the second for

the ramp, and so forth (see figs 4-4 and 4-5). For

the C–5, rolling shoring may have to be leap-

frogged, depending on the desired tiedown

location.

(2) Parking/sleeper shoring is to be applied as

shown in figures 4–6 and 4–7.

c.

Loadmaster Responsibilities.

The loadmaster

will ensure that the vehicle is loaded and secured

in accordance with the applicable TO 1C–XXX–9.

4-4. Safety

Besides the safety precautions contained in chap-

ter 3, the following considerations should be noted:

a. The height of the M9 ACE must be reduced

for transport in C-130 and C-141 aircraft.

b.

Sleeper and parking shoring are required in

all aircraft.

c. Relieve track tension until the track lies

directly on top of road wheel four prior to loading

aboard the aircraft.

d.

Position suspension to the UNSPRUNG mode

for loading/offloading and to the SPRUNG mode

for flight.

e. The fuel load must be reduced to 25 percent,

and the components must be repositioned in the

bowl before loading operations.

f. Once the vehicle is loaded in the aircraft,

relieve the hydraulic pressure to allow the vehicle

to settle on the bump stops faster.

4-5. Preparation of Vehicle

a.

Personnel Requirement.

At least one heavy

equipment operator, heavy equipment mechanic,

and wrecker operator are required to prepare,

load, unload, and place the M9 ACE in operation.

Additional support personnel (MOS immaterial)

with minimum familiarization of the equipment

will reduce preparation time.

b. Equipment and Materials.

The following

equipment and materials are required for prepar-

ing and placing the M9 ACE in operation:

(1) T

OO

l

kit, mechanic

(2) Wrecker, 5-ton

(3) Shoring (tables 4-4 and 4-5)

(4) Socket set, heavy-duty, 3/4-inch drive

(5) Handle, socket, 3/4-inch square drive, 20-

l/2-inch length

c.

Preparation Times.

Time required for prepar-

ing, loading, offloading, and placing the M9 ACE

in operation will vary depending on existing condi-

tions and personnel available. Time and personnel

allotted to each operation are for planning pur-

poses.

4-1

Back to Top