TM-9-2320-260-34-1 - Page 376 of 657

TM 9-2320-260-34-1

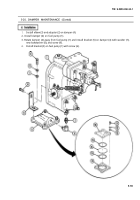

5-21. FUEL PUMP AIR CYLINDER MAINTENANCE

THIS TASK COVERS:

a. Removal

c. Adjustment

b. Installation

INITIAL SETUP

APPLICABLE MODELS

M816, M819

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

MATERIALS/PARTS

Two lockwashers (Appendix D, Item 225)

Antiseize tape (Appendix C, Item 50)

REFERENCES (TM)

TM 9-2320-260-10

TM 9-2320-260-34P-1

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-260-10).

Hood raised and secured (TM 9-2320-260-10).

Air reservoirs drained (TM 9-2320-260-10).

GENERAL SAFETY INSTRUCTIONS

Do not disconnect air line before draining air

reservoirs.

Hearing protection must be worn when

performing this task.

a. Removal

WARNING

Do not disconnect air line before draining air reservoirs. Small

parts under pressure may shoot out with high velocity, causing

injury to personnel.

1.

Remove air line (4) and adapter (3) from air cylinder (2).

2. Remove nut (1) and air cylinder (2) from bracket (7).

3. Remove two screws (5), lockwashers (6), and bracket (7) from fuel pump (8). Discard lockwashers (6).

b. Installation

1.

Install bracket (7) on fuel pump (8) with two new lockwashers (6) and screws (5).

2. Install air cylinder (2) on bracket (7) with nut (1).

3. Apply antiseize tape to male threads of adapter (3) and air line (4) and install adapter (3) and air

line (4) on air cylinder (2)

c. Adjustment

Hearing protection must be worn by mechanic when engine is

running. Noise levels produced by this vehicle exceed 85dB, which

may cause injury to personnel.

1. Start engine (TM 9-2320-260-10) and allow air system to reach normal operating pressure.

NOTE

Perform step 2 for M816 wrecker truck.

2. Engage crane drive control lever (TM 9-2320-260-10).

3. Engage transfer power takeoff lever (TM 9-2320-260-10).

5-56

Back to Top