TM-9-2320-260-34-1 - Page 580 of 657

TM 9-2320-260-34-1

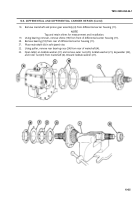

10-8. DIFFERENTIAL AND DIFFERENTIAL CARRIER REPAIR

THIS TASK COVERS:

a. Disassembly

c.

Assembly and Adjustment

b. Cleaning, Inspection, and Repair

INITIAL SETUP

APPLICABLE MODELS

All

SPECIAL TOOLS

Differential flange replacer

(Appendix B, Item 60)

Bearing cup replacer (Appendix B, Item 98)

Bearing cup replacer (Appendix B, Item 99)

TOOLS

General mechanic’s tool kit

(Appendix B, Item 1)

Bearing preload scale (Appendix B, Item 32)

Wheel bearing nut wrench

(Appendix B, Item 48)

Mechanical puller kit (Appendix B, Item 14)

Inside caliper micrometer

(Appendix B, Item 9)

Vernier caliper (Appendix B, Item 33)

Outside caliper micrometer

(Appendix B, Item 8)

Arbor press (Appendix B, Item 7)

2-1/4-in. socket, 1-in. dr.

(Appendix B, Item 34)

Bearing installer/remover

(Appendix B, Item 83)

Torque wrench, 1/2-in. dr.

(Appendix B, Item 3)

Torque wrench, 3/4-in. dr.

(Appendix B, Item 2)

Vise (Appendix B, Item 38)

Adapter, 3/4-in. to l-in. dr.

(Appendix B, Item 19)

1-1/8-in. socket, 3/4-in. dr.

(Appendix B, Item 37)

Soft-head hammer (Appendix B, Item 47)

Bearing adapter (Appendix B, Item 35)

Chain

Lifting device

MATERIALS/PARTS

Wear sleeve kit (Appendix D, Item 337)

Gasket and shim set (Appendix D, Item 485)

Bevel pinion gear spacer kit (Appendix D, Item 333)

Six lock washers (Appendix D, Item 215)

Locktab washer (Appendix D, Item 207)

Two cotter pins (Appendix D, Item 25)

Two oil seals (Appendix D, Item 430)

Gasket (Appendix D, Item 150)

Six lockwashers (Appendix D, Item 223)

Crocus cloth (Appendix C, Item 53)

GAA grease (Appendix C, Item 14)

Lubricating oil (Appendix C, Item 22)

Blue oil base pigment (Appendix C, Item 26)

Sealing compound (Appendix C, Item 43)

Sealing compound (Appendix C, Item 44)

Sealing compound (Appendix C, Item 42)

Twine (Appendix C, Item 54)

White carbonate pigment (Appendix C, Item 27)

Safety wire (Appendix C, Item 59)

REFERENCES (TM)

LO 9-2320-260-12

TM 9-214

TM 9-2320-260-20

TM 9-2320 -260-34P-1

EQUIPMENT CONDITION

Differential and carrier assembly removed

(para. 10-7).

GENERAL SAFETY INSTRUCTIONS

Keep fire extinguisher nearby when using

drycleaning solvent.

Compressed air source will not exceed 30 psi

(207 kPa).

Eyeshields must be worn when cleaning with

compressed air.

a.

Disassembly

NOTE

Front and rear differentials are repaired the same way.

1. Remove safety wires (1) from two screws (2) and four screws (4). Discard safety wires (1).

2. Remove two screws (2) and adjusting nut locks (3) from beating caps (6).

10-22

Back to Top