TM-9-2320-272-10 - Page 131 of 481

TM 9-2320-272-10

2-32

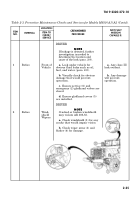

Wetness around seals, gaskets, fittings, or connections indicates leakage. A stain

also denotes leakage. If a fitting or connector is loose, tighten it. If broken or defec-

tive, report it. Use the following as a guide when referring to table 2-2, Fluid

Leakage Criteria for Tactical Vehicles:

a.

Class I.

Leakage indicated by wetness or discoloration not great enough to

form drops.

b.

Class II.

Leakage great enough to form drops, but not enough to cause

drops to drip from item being checked/inspected.

c.

Class III.

Leakage great enough to form drops that fall from the item being

checked/inspected.

2-9. CLASS LEAKAGE DEFINITIONS

2-8. CLEANING INSTRUCTION AND PRECAUTIONS (Contd)

Cleaning Materials Used to Remove

** After cleaning, apply grease (MIL-B-18458).

Surface

Rubber

Insulation

Tires

Wire Rope

Wood

Oil/Grease

Damp or dry rags.

Soapy water and

bristle brush.

Cleaning com-

pound and wire

brush.

Detergent, warm

water, and damp

or dry rags.

Salt/Mud/Dust/Debris

Damp or dry rags.

High pressure water and

bristle brush.

Wire brush.

Low pressure water,

soapy warm water, and

damp or dry rags.

Surface Rust/Corrosion

Not applicable.

Not applicable.

Wire brush and lubricat-

ing oil.**

Not applicable.

Table 2-1. General Cleaning Instructions (Contd).

WARNING

Accidental or intentional introduction of liquid contaminants into

the environment is in violation of state, federal, and military regu-

lations. Refer to Lubrication Order (para. 3-1) for information con-

cerning storage, use, and disposal of these liquids. Failure to do so

may result in injury or death.

Back to Top