TM-9-2320-272-10 - Page 179 of 481

2-78

Table 2-3. Preventive Maintenance Checks and Services for Models M939/A1/A2 (Contd).

ITEM

NO.

INTERVAL

ITEM TO

CHECK/

SERVICE

NOT FULLY

MISSION

CAPABLE IF:

TM 9-2320-272-10

LOCATION

CREWMEMBER

PROCEDURE

Battery is cracked,

unserviceable,

missing, or leaking.

Terminals or cables

are loose or corrod-

ed, or hold downs

are not secure.

DRIVER

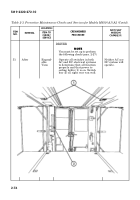

WARNING

• Don’t smoke, have open

flames, or make sparks around

the batteries, especially if the

caps are off. Batteries can

explode and cause injury or

death.

• Protective clothing, rubber

gloves, and eye protection

must be worn.

• Remove all jewelry such as

rings, dog tags, or bracelets. If

jewelry or tools contact battery

terminal, a direct short may

occur resulting in instant

heating, damage to equipment,

and injury to personnel.

• Ensure seatbelts and strap-

ping do not come in contact

with electrolyte. Damage to

strapping material will result,

leading to injury or death.

• Ensure seatbelts are not

caught inside battery box

when closing cover. Failure to

do so will result in injury or

death.

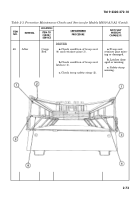

a.

Check electrolyte level in bat-

tery (2). Electrolyte should be filled

to the level/split ring (3) in the bat-

tery filler opening (vent). If fluid is

low, fill with distilled water to the

level ring. If fluid is gassing (boil-

ing), notify unit maintenance.

b.

Inspect seatbelt straps (1) for

damage from electrolyte.

Batteries

Weekly

53

Back to Top