TM-9-2320-272-23-1 - Page 255 of 1313

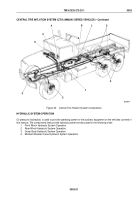

CENTRAL TIRE INFLATION SYSTEM (CTIS) (M939A2 SERIES VEHICLES)

The M939A2 Central Tire Inflation System (CTIS) uses the vehicle's air compressor system, pneumatic valves, and

a microprocessor to adjust tire pressure according to mission demands. The system needs clean, dry air to maintain

itself. The turbocharger and aftercooler help supply more compressed air when the vehicle is loaded and operating

at high rpm.

Compressed air enters air dryer, which filters dirt and ejects moisture from air. System air then enters the wet tank

and is available to airbrakes and CTIS. The brake system is protected by an 85 psi (138 kPa) pressure switch in

CTIS air line. If wet tank air pressure measures below 85 psi (138 kPa), the CTIS shuts down until pressure switch

measures 120 psi (827 kPa).

Air is then routed to pneumatic controller, which consists of three valves and solenoids working in conjunction with

the Electronic Control Unit (ECU). The ECU is a microprocessor programmed to issue commands based on

information it receives from pressure switch, pressure transducer (which tests tires pressure), and speed signal

generator (which monitors vehicle speed). The commands are electrically received by the pneumatic controller,

which affects inflation or deflation of tires through quick-exhaust valves.

Six wheel valves isolate tire pressure during normal operation. They also open to allow tire inflation or tire deflation

through three quick-exhaust valves.

The system is automatic. The operator only needs to select the mode that best accomplishes the mission.

The CTIS is common to all M939A2 series vehicles. This system maintains tire air pressure depending on which

road type is selected. If this setting is changed, tires will automatically inflate or deflate to the new setting.

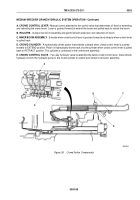

A. ELECTRONIC CONTROL UNIT (ECU)

- Contains CTIS selector panel so that operator can change tire

inflation during vehicle operation.

B. AIR PRESSURE SWITCH

- Protects air brake system for a minimum supply of 85 psi (586 kPa) of air.

C. AIR DRYER AND FILTER

- Separates moisture from compressed air system and filters impurities from

compressed air before they enter CTIS.

D. EXHAUST VALVES

- Exhaust air from tires during deflation.

E. WHEEL VALVES

- Isolate air pressure in tires during normal operation and for tire removal.

F. SPEED SIGNAL GENERATOR

- Signals ECU to automatically inflate CTIS when vehicle speed exceeds

the top speed setting for the selected mode by 10 mph (16 kmh).

G. PNEUMATIC CONTROLLER

- Directs air pressure according to ECU commands.

H. PRESSURE TRANSDUCER

- Mounted in pneumatic controller, it measures tire pressure and sends

information to ECU.

TM 9-2320-272-23-1

0003

0003-50

Back to Top