TM-9-2320-272-24-1 - Page 349 of 1015

TM 9-2320-272±24²1

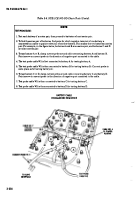

table ³´6. StE I iCE NOµGO¶Cha·n tes¸s (Con¸d)¹

ºg

»V¼Rº½R/PW¼R ¾¿ FAULÀ ÁÂÃÄÅ

cÆuÇÈÉÊ

Check that air inlet Is cLeaR of tooLs, debR±s² d³Rt²

and dust befORe peRfORm±ng FLLowIng test.

rËVÌ Ír ÎÏмR Ñ r¼pAÀ ÒwR À¼ÓÀ:

•

´Emove air cLeaner µom ¶ntake hoUsIng·

•

´epeaT PoweR TesT G06² sTep

2.

•

Does en¸±ne pass poweR tesT w¹tH a¹R cLeaneR oUt?

•

´einsTaLL a±R cLeaneR

(paRa·

ÔÕÖ5×Ø

cÆuÇÈÉÊ

•

Do not PeRfoRm moRe tHan

2

compRessºon

unbaLance tests in a Row to p»eVent

d¶schaRge of ¼eh½cLe batteRIes·

•

¾n¸ine mUst be at noRmaL opeRat±ng

tempeRatURe be¿Re pe»foRmIng

compRess±on Unbalance test·

ÊÉÙÚ

Àhe compRess±on Unbalance test takes

apProxÁmately

Û5

Seconds to ÂnÃ

•

Äroceed to neXt paÅeÆ

•

ÇnstaÈL a new aiR ÉÊLteR

ËpaRa·

ÔÜÝÔ

oR

ÔÜÝÞ×ß

ÊÉàÚ

AteR comPLeT±ng RePaIR² ReRUn GÌ-CHaIn

tesÍ to Ve»±fY tHe pRoblem ±s ÎXed and no

otheR pRobLems eX³st·

áâáãä

Back to Top