TM-9-2320-272-24-4 - Page 220 of 836

TM 9-2320-272-24-4

5-32. FUEL INJECTION PUMP PRETEST

THIS TASK COVERS:

a. Prestroke and Rack Travel

b. Cylinder Phasing (Timing)

c. High-speed Fuel Delivery Test

g. Manifold Pressure Compensator Test

h. Start Cut Out Test

I. Fuel Delivery Test

d. Low-speed Fuel Delivery Test

j. Fuel Breakaway Test

e. Rated Speed Test

k. Starting Fuel Delivery Test

f. Full Load Delivery

l. Low Idle Fuel Delivery Test

INITIAL SETUP:

APPLICABLE MODELS

MATERIALS/PARTS

M939A2

Two copper washers (Appendix D, Item 42)

SPECIAL TOOLS

REFERENCES (TM)

Rack extension (Appendix E, Item 112)

TM 9-2320-272-24P

Plunger lift device (Appendix E, Item 98)

TM 9-4910-778-14&P

TOOLS

EQUIPMENT CONDITION

General mechanic’s tool kit (Appendix E, Item 1)

Dial Indicator (Appendix E, Item 36)

Fuel injection pump mounted to test stand (para. 5-31).

NOTE

Refer to TM 9-4910-778-14&P for operation of fuel injection

pump test stand, DFP 156.

If readings taken during pretest deviate from specifications

listed below, fuel pump must be repaired.

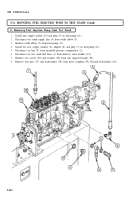

a. Prestroke and Rack Travel

1.

2.

3.

4.

5.

6.

7.

Mount dial indicator (4) on plunger lift device (5) and zero dial indicator (4).

8.

Manually rotate test stand driveshaft (8) until a reading is observed on dial indicator (4).

9.

Manually reverse rotation test stand driveshaft (8) until dial indicator (4) reads zero.

10.

Apply 435-464 psi (2,999-3,190 kPa) of calibration fluid pressure.

Mount dial indicator (10) and rack travel indicator holder (9) on drive end of fuel pump (13).

Install rack extension (11) on control rack (12).

Pull control lever (2) to full load position and, using rack extension (11), push control rack (12) all

the way back.

Preload dial indicator (10) giving control rack (12) 0.004 in. (0.1 mm) of preload travel.

Install plug (3) in return line access hole (14).

NOTE

Cylinder number one is located at drive end of fuel pump.

Rotate test stand driveshaft until tappet reaches bottom dead

center.

Install plunger lift device (5) on fuel pump (13) with finger of plunger lift device (5) resting on top of

tappet located in cylinder number one.

5-214

Back to Top