TM-9-2320-272-24-4 - Page 276 of 836

TM 9-2320-272-24-4

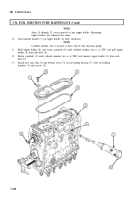

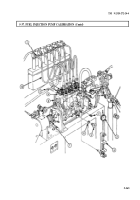

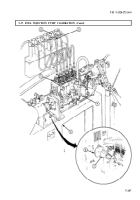

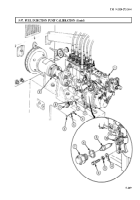

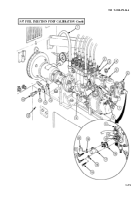

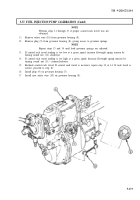

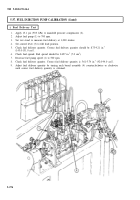

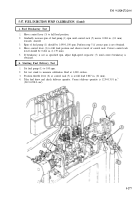

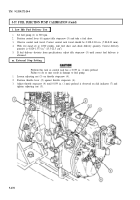

5-37. FUEL INJECTION PUMP CALIBRATION (Contd)

d. High-speed Fuel Delivery Test

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

NOTE

l

Maintain 22 psi (152 kPa) calibration fluid pressure throughout

this task.

l

Close all bleedoff valves.

Set test stand (12) to measure fuel delivery at 1,000 strokes.

Remove plug (4) from top of governor housing (5) and pour two pints of lubricating oil in governor

housing (5).

Remove plug (13) and washer (10) from fuel pump (9).

Install new copper washer (10), adapter (11), new copper washer (10), and plug (13) on fuel pump (9).

Connect return line (1) to adapter (11).

Adjust fuel pump (9) to 1,050 rpm.

NOTE

Adjust aneroid air pressure to help obtain correct rack travel.

Adjust control lever (8) to obtain rack travel of 0.360-0.480 in. (9.14-12.19 mm).

NOTE

Perform steps 8 and 9 if correct rack travel is not obtained.

Remove breakoff screw (19), screw (21), two lockwashers (18), protective cap (17), and stop (16) from

manifold pressure compensator (6). Discard breakoff screw (19) and two lockwashers (18).

Turn nuts (15) and (14) counterclockwise to increase rack travel; or clockwise to decrease rack

travel.

Position control lever (8) to full load and take fuel draw.

Check fuel delivery. Correct fuel delivery should be 0.891-0.928 in.

3

(14.6-15.2 cm

3

).

Allowable spread reading is 0.037 in.

3

(0.6 cm

3

).

NOTE

l

Perform step 13 if fuel delivery deviates from specifications.

l

Step 13 pertains to one cylinder only.

Loosen three nuts (2) and rotate barrel (3) clockwise to increase fuel delivery; counterclockwise to

decrease fuel delivery.

Repeat step 13 for remaining cylinders.

Install stop (16) and protective cap (17) on manifold pressure compensator (6) with two new

lockwashers (18), screw (21), and new breakoff screw (20).

Install new safety wire (22) on screw (21) and protective cap (17).

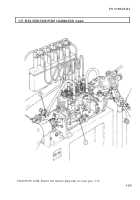

e. Low-speed Fuel Delivery Test

NOTE

Maintain 22 psi (152 kPa) calibration fluid pressure throughout

this task.

1.

Reduce fuel pump (9) to 300 rpm.

2.

Set control rack travel at 0.308-0.316 in. (7.8-8.0 mm).

3.

Check fuel delivery. Correct fuel delivery should be 0.079-0.134 in.

3

(1.3-2.2 cm

3

).

4.

Allowable spread reading is 0.030 in.

3

(0.5 cm

3

).

5.

If low-speed fuel delivery deviates from specifications given, adjust low idle stopscrew (7) until

correct fuel delivery is obtained.

5-270

Back to Top