TM-9-2320-272-24-4 - Page 392 of 836

TM 9-2320-272-24-4

5-60. TRANSMISSION OIL PRESSURE TESTING

THIS TASK COVERS:

a. Oil Cooler Pressure Test

b. Main Pressure and Governor

Pressure Test

c. Automatic Shift Speed Test

INITIAL SETUP:

APPLICABLE MODELS

All

REFERENCES (TM)

TM 9-2320-272-10

TM 9-2320-272-24P

SPECIAL TOOLS

Pressure gauge set (300 psi) (Appendix E,

Item 51)

TOOLS

EQUIPMENT CONDITION

Parking brake set (TM 9-2320-272-10).

Transmission oil at proper level (TM 9-2320-272-10).

Vehicle at curb weight (empty) (TM 9-2320-272-10).

General mechanic’s tool kit (Appendix E, Item 1)

Wheels blocked (chocked) (TM 9-2320-272-10).

Drill press

21/64 drill bit

SPECIAL ENVIRONMENTAL CONDITIONS

1/4-18 NPTF tap

Work area clean and free from blowing dirt and

Pipe plug

dust.

Two pipe plugs

MATERIALS/PARTS

O-ring (Appendix D, Item 430)

GENERAL SAFETY INSTRUCTIONS

Personnel must be clear from underside and front of

vehicle when engine is running.

Cap and plug set (Appendix C,

Item 14)

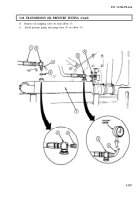

a. Oil Cooler Pressure Test

CAUTION

Before disconnecting transmission pressure lines, clean surrounding

surfaces and plug all openings to prevent entry of dirt or debris into

transmission. Damage will occur if dirt or debris enters transmission.

1.

Disconnect oil cooler supply hose (1) from elbow (2) on top of oil cooler (7).

NOTE

Note elbow alignment for connection.

2.

Loosen nut (3) and remove elbow (2) and O-ring (4) from oil cooler (7). Discard O-ring (4).

3.

Using drill press and 21/64 drill bit, drill hole in side of elbow (2) opposite hose port.

4.

Tap hole in elbow (2) with 1/4-18 NPTF tap.

CAUTION

After tapping, elbow must be thoroughly cleaned and all burrs

and shavings removed. Any shavings entering system will damage

transmission.

5.

Remove elbow (2) from drill press and thoroughly clean.

6.

Install new O-ring (4) and elbow (2) in oil cooler (7) until aligned as noted in step 2.

7.

Tighten nut (3) until O-ring (4) is seated.

8.

Install pipe plug (8) on elbow (2).

9.

Connect oil cooler supply hose (1) to elbow (2).

5-386

Back to Top