TM-9-2320-279-20-1 - Page 34 of 985

TM 9-2320-279-20-1

Safety and Handling

1-14. SAFETY, CARE, AND HANDLING.

a. Significant Hazards and Safety Recommendations.

Significant hazards and safety

recommendations are listed in Table 1-3.

Table 1-3. Significant Hazards and Safety Recommendation s

Operatin g

Hazar d

Safety Recommendation or Precaution

Condition¹

Low air pressure for

Do not drive vehicle while low air pressure warning

Abnormal

brakes.

buzzer is sounding or red light is on.

Vehicle instability with

Ensure that outriggers are down on firm ground, side

Abnormal

crane use.

slope does not exceed five degrees, and crane is not

overloaded.

Fire with M978 tanker.

No smoking, flames, or sparks within 50 feet (15 m).

Normal

Disconnect batteries for all electrical work.

Fuel spills with M978

Test tank automatic shutoff before bottom loading

Abnormal

tanker.

per procedure in instructions. Do not bypass

dead-man controls.

Connecting towing devices.

Do not go between vehicles until vehicles are

Normal

stopped and brakes are set.

Refueling vehicle.

Shut off engine and no smoking when filling tank.

Normal

¹Category of hazards as to whether or not they may be expected under normal or abnormal operating

conditions.

b. Cranes.

Material handling cranes for models M977, M983, M984, M984E1, M985, and M985E1 all

have overload shutdown and/or tilt warning (unstable) systems.

(1) On M983, M984, and M985E1 models a yellow caution light at fixed operator’s station and an

audible warning signal alert the operator when an unstable crane condition occurs.

(2) M983, M984, and M985E1 have an overload shutdown system which senses lift cylinder pressure

to prevent overloading the crane. The system will shut down the crane to prevent hoisting, boom

extension, or boom raising when an overload condition exists. Load lowering and boom retraction

functions will not be affected.

(3) When M977, M985, and M984E1 cranes are overloaded, the overload system will automatically

shut off power to telescope boom out, raise boom, or hoist load higher. The M977 and M984E1 overload

system, will also prevent lowering the boom. An overload condition can be corrected by lowering load to

ground or other supporting surface. All crane functions will be restored in approximately six seconds.

c. Crane Operating Instruction Plate Locations :

(1) The crane operating instruction plates are located on the heater compartment cover in the cab,

and at each of the fixed operating stations.

(2) The outrigger leg signs are located on each of the outrigger cylinders.

(3) The load capacity signs are located at the main and auxiliary control panels and on M984E1, they

are also located on the wrecker body rear stowage box doors.

Section Ill .

PRINCIPLES OF OPERATION .

Vehicle Operation Systems

1-15. POWER TRAIN.

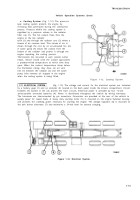

(fig. 1-9) Power for the vehicle is provided by a diesel engine (1) which is

coupled directly to an automatic transmission (2). Power from the transmission is transferred to the

transfer case (3) and on to the front and rear axles (4) through a series of propeller shafts and universal

joints (5).

1-1 2

Back to Top