TM-9-2320-280-34 - Page 1012 of 1258

TM 9-2320-280-34

19 - 3. DIFFERENTIAL REPAIR (Cont ’d)

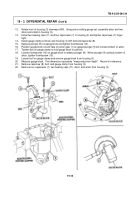

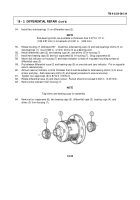

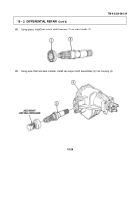

48.

Rotate housing (3) 90 °

.

Lubricate rear pinion bearing (6) with lubricating oil.

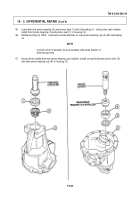

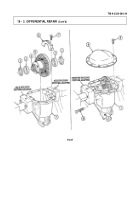

CAUTION

Collapsible spacer controls pinion bearing preload. Do not reuse

old spacer or pinion bearing damage may result.

49.

Install collapsible spacer (8) on pinion gear (7) and install pinion gear (7) in housing (3).

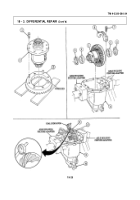

50.

Install pinion yoke (9) with locknut (10) on pinion gear (7).

CAUTION

Do not exceed specified preload torque on pinion bearings.

Do not

loosen locknut to replace preload torque or pinion bearing damage

may result.

If specified torque is exceeded, remove pinion gear and

replace collapsible spacer and locknut and adjust preload again.

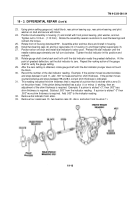

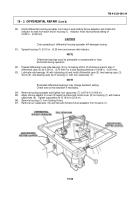

51.

Tighten locknut (10) only enough to remove end play and seat pinion bearings in housing (3).

Rotate

pinion yoke (9) while tightening, to seat bearings evenly.

52.

Measure torque required to rotate pinion gear (7).

Correct pinion bearing preload torque is

17-25 lb-in.

(2-3 N.m) with new bearings and 10-15 lb-in.

(1-2 N.m) with used bearings.

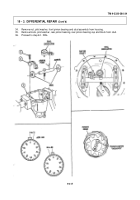

53.

Continue to tighten locknut (10) in small increments until pinion bearing preload torque meets

specifications.

19-21

Back to Top