TM-9-2320-280-34 - Page 976 of 1258

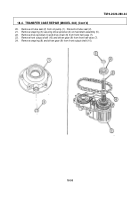

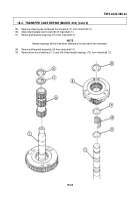

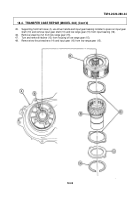

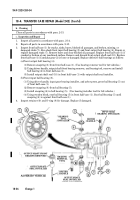

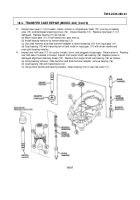

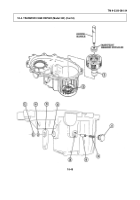

1 8 - 4 . TRANSFER CASE REPAIR (Model 242) (Cont'd)

TM 9-2320-280-34

18-36

Change 1

Clean all parts in accordance with para. 2-13.

1.

Inspect all parts in accordance with para. 2-14.

2.

Repair all parts in accordance with para. 2-15.

3.

Inspect front half-case (1) for cracks, nicks, burrs, blocked oil passages, and broken, missing, or

damaged studs (7). Also check front input ball bearing (5) and front output ball bearing (4). Repair or

replace damaged studs (7). Remove burrs and clear blocked oil passages. Replace front half-case (1) if

cracked or broken at any machined surface. Remove and discard front output shaft seal (10). Replace

front half-case (1) if annulus gear (2) is loose or damaged. Replace defective ball bearings as follows:

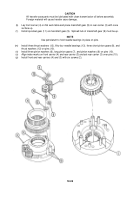

(a)Front output ball bearing (4).

(1) Remove snapring (3) from front half-case (1). (Use bearing remover tool for A2 vehicles.)

(2) Using driver handle, output shaft front bearing remover, and bearing tool, remove and install

ball bearing (4) in front half-case (1).

(3) Install output shaft seal (10) in front half-case (1) with output shaft seal installer.

(b)Front input ball bearing (5).

(1) Using driver handle, input gear bearing installer, and arbor press, press ball bearing (5) out

of front half-case (1).

(2) Remove snapring (6) from ball bearing (5).

(3) Install snapring (6) in ball bearing (5).

(Use bearing installer tool for A2 vehicles.)

(4) Using wooden block, seat ball bearing (5) in front half-case (1). Seat ball bearing (5) until

snapring (6) is against front half-case (1).

4.

Inspect retainer (9) and O-ring (8) for damage. Replace if damaged.

c. Inspection and Repair

b. Cleaning

DRIVER

HANDLE

DRIVER

HANDLE

BEARING

TOOL

INSTALLER

BEARING

REMOVAL

TOOL

INPUT GEAR

BEARING INSTALLER

OUTPUT SHAFT FRONT

BEARING REMOVER

OUTPUT SHAFT

SEAL INSTALLER

OUTPUT SHAFT

SEAL INSTALLER

A2 SERIES VEHICLE

Back to Top