TM-9-2320-361-34 - Page 287 of 764

TM 9-2320-361-34

I

13-3. FRAME ALINEMENT INSPECTION (Contd)

NOTE

●

Any loose or missing cross member rivets, loose or

broken

crossmembers, or damaged frame rails must be repaired prior to

inspection.

●

Ensure inspection

procedure

is

performed

on

a

flat level

surface.

I

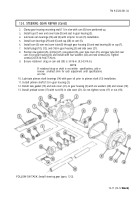

a. Frame Leveling

1.

Drive truck into inspection position from a 12 ft (3.7 m) straight line of travel. Apply parking brake

(TM 9-2320-361-10) and chock wheels (TM 9-2320-361-10).

2.

Using tape measure, determine distance from floor (3) to bottom of front flame rails (1) in front of

crossmember (4). If one frame rail (1) is lower, use hydraulic jack and raise one side of front axle to

level frame rails (1) to within 1/8 in. (3 mm) of each other.

3. Using tape

measure,

determine

distance from floor (3) to bottom of rear frame rails (1) at cross-

member (2). If one frame rail (1) is lower, use hydraulic jack and raise one side of rear-rear axle to

level frame rails (1) to within 1/8-5/16 in. (3-8 mm) of each other.

I

b.

Horizontal Bow Inspection, Frames 20 Ft (6 M) or Less

1. Tape one 8 x 10-1/2 in. (20x 27 cm) sheet of white paper to floor (3) under each end of frame

crossmembers (6) and in front of crossmember (4) where attached to frame rails (1).

2. Tape one 8 x 10-1/2 in. (20x 27 cm) sheet of white paper to floor (3) under each front bogie

bracket (5).

NOTE

Ensure plumb bob string is placed flat against frame rails free of

obstructions such as bolts, rivets, brackets, and rear springs. Allow

plumb bob to stop swinging before making mark on paper.

3.

Hold string with plumb bob to outside of frame rails (1), above paper, and 4 in. (10 cm) up from

bottom of frame rails (1). Accurately locate point of paper directly below plumb bob.

4.

Carefully mark spot on each paper directly below plumb point.

13-2

Back to Top