TM-9-2320-365-10 - Page 779 of 836

TM 9-2320-365-10

Change 2

F-1

APPENDIX F

LUBRICATION ORDER AND SERVICES

Section I.

INTRODUCTION

F-1.

GENERAL

This appendix gives lubrication/service requirements for the vehicle which are the

responsibility of the Operator/Crew.

a.

Adherence.

Intervals (on-condition or hard time) and the related man-hour times are

based on normal operation.

The man-hour time specified is the time needed to do all

the services prescribed for a particular interval.

On-condition (OC) oil sample intervals

shall be applied unless changed by the Army Oil Analysis Program (AOAP)

laboratory.

Change the hard time interval if lubricants are contaminated or if operating

the equipment under adverse operating conditions, including longer-than-usual

operating hours.

The calendar interval may be extended during periods of low activity.

If extended, adequate preservation precautions must be taken.

Hard time intervals

will be applied in the event AOAP laboratory support is not available.

Hard time

intervals must be applied during the warranty period.

Intervals shown in this lubrication order and services are based on mileage/calendar

times.

The lubrication/services for the vehicle is to be performed at whichever interval

occurs first.

•

Dry Cleaning Solvent (P-D-680) is TOXIC and flammable.

Wear

protective goggles and gloves; use only in well-ventilated area;

avoid contact with skin, eyes, and clothes, and do not breath

vapors.

Keep away from heat or flame.

Never smoke when using

solvent; the flashpoint for Type I Dry Cleaning Solvent is 100 F

(38 C) and for Type II is 138 F (50 C).

Failure to comply may result

in serious injury or death to personnel.

•

If personnel become dizzy while using cleaning solvent,

immediately get fresh air and medical help.

If solvent contacts skin

or clothes, flush with cold water.

If solvent contacts eyes,

immediately flush eyes with water and get medical attention.

Failure to comply may result in serious injury or death to personnel.

b.

Cleaning Fittings Before Lubrication.

Clean parts with Dry Cleaning Solvent (SD

P-D-680) or equivalent.

Dry before lubricating.

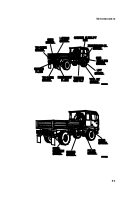

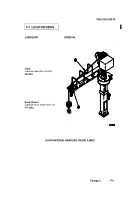

Dashed arrows indicate lubrication on

both sides of the equipment.

c. Lubrication After Fording.

If a fording operation occurs, lubricate all fittings below

fording depth and check submerged gear boxes for presence of water.

WARNING

Back to Top