TM-9-2320-365-20-4 - Page 708 of 968

TM 9-2320-365-20-4

19-6. CAB HYDRAULIC LATCH REPLACEMENT/ADJUSTMENT

This task covers:

a. Removal

b. Installation

c. Adjustment

d. Follow-On Maintenance

INITIAL SETUP

Equipment Conditions

Engine shut down (TM 9-2320-365-10).

Cab raised (TM 9-2320-365-10).

Tools and Special Tools

Tool Kit, Genl Mech (Item 44, Appendix C)

Goggles, Industrial (Item 15, Appendix C)

Gloves, Rubber (Item 13, Appendix C)

Pan, Drain (Item 24, Appendix C)

Wrench, Torque, 0-175 lb-ft (Item 57, Appendix C)

Materials/Parts

Cap and Plug Set (Item 15, Appendix D)

Nut, Self-Locking (4) (Item 149, Appendix G)

Hydraulic Fluid A (Item 26, Appendix D)

a. Removal.

(1) Position drain pan under hydraulic hose (1).

WARNING

Hydraulic fluid (MIL-H-5606A) is TOXIC.

Wear protective goggles and gloves; use

only in well ventilated area; avoid contact

with skin,

eyes, and clothes. Skin and

clothing

that

come

in

contact

with

hydraulic

oil

should

be

washed

immediately.

Saturated clothing should

be

removed

immediately.

Failure

to

comply may result in injury to personnel.

CAUTION

Cap or plug hydraulic hose and connection

point to prevent contamination of hydraulic

system.

Failure to comply may result in

damage to equipment.

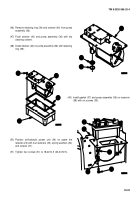

(2) Disconnect hydraulic hose (1) from 90-degree fitting (2).

(3) Remove four self-locking nuts (3), washers (4), screws

(5), and hydraulic latch (6) from cab support assembly

(7). Discard self-locking nuts.

(4) Remove 90-degree fitting (2) from hydraulic latch (6).

19-24

Change 1

Back to Top