TM-9-2320-366-20-1 - Page 1631 of 1824

TM 9-2320-366-20-1

Change 2

H-27

5.

FUEL/WATER SEPARATOR.

Replace filter element every 6,000 miles (9,654 km) or once every six months,

whichever occurs first (para 4-13).

6.

FUEL FILTER.

The fuel particle filter is replaced when a new fuel/water separator filter element is installed.

The

normal replacement interval is every 6,000 miles (9,654 km) or once every six months, whichever occurs first (para 4-14).

7.

ENGINE COOLANT.

Check engine coolant level daily.

Change the coolant and flush the cooling system every

24,000 miles (38,616 km) or once every two years, whichever occurs first.

Fill radiator overflow tank with an Ethylene

Glycol/water mixture as specified in 0-A-548D.

Service the cooling system before the specified interval if:

•

Coolant is heavily contaminated.

•

Engine overheats.

•

Oil cooler has failed allowing oil and coolant to mix.

8.

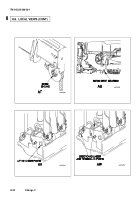

HYDRAULIC RESERVOIR AND FILTER (All Models Except M1089).

Check oil level weekly and make sure oil

level gage reads

F (full)

.

Units participating in AOAP will sample oil annually and change oil and filter as directed by

AOAP.

Units not participating in AOAP will change oil and filter every two years.

Drain oil and refill hydraulic reservoir

with OE/HDO specified for ambient operating temperature.

Fill hydraulic reservoir until oil level gage reads

F (full).

Do

not overfill.

Replace oil filter each time oil is changed (para 19-13).

9.

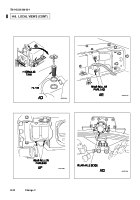

DRIVE SHAFT UNIVERSAL and SLIP YOKE.

Lubricate drive shafts with GAA every 3,000 miles (4,827 km) or once every three months, whichever occurs first, using a

low pressure lubrication gun.

If operating conditions are severe or abnormal, service at 1,000 miles (1,609 km) or once

every month, whichever occurs first.

Perform drive shaft hinging inspection every time drive shafts are serviced (para 9-

3).

•

UNIVERSAL JOINT:

A. Apply grease to both grease fittings until new grease purges from all four bearing caps.

B. If grease does not purge from all four bearing caps, perform the following steps:

(1)

Loosen two screws on bearing cap that does not purge, approximately 1/4 in.

(2)

Apply grease to grease fitting for bearing cap that does not purge until bearing cap purges.

(3)

Remove and discard the two screws loosened in step (1).

(4)

Position two replacement screws in bearing cap and tighten down evenly.

(5)

Tighten two screws to 26-35 lb-ft (35-47 N

m).

•

SLIP JOINT:

A. Apply grease until grease appears at the vent in the welch plug.

B. Place your finger over the welch plug vent and add grease until grease purges from the dust seal.

C. If grease does not purge from the dust seal, inspect drive shaft slip yoke (para 9-2).

10. AIR/HYDRAULIC POWER UNIT and BACKUP HYDRAULIC PUMP.

Change OHA oil every 24,000 miles (38,616

km) or once every two years, whichever occurs first.

To service air/hydraulic power unit and backup hydraulic pump refer

to vehicle para 19-8, Air Transportability Hydraulic System Service.

11. ALL AXLE DIFFERENTIALS.

Check oil level in differentials every 3,000 miles (4,827 km).

Check oil level with

vehicle parked on level surface and axle differential at ambient temperature, allowing at least one hour to cool down after

vehicle operation.

If oil is checked when axle differential is hot, it is normal for oil to spill out of the port due to expansion

from the heat.

Oil level is considered full if it is within one inch of the bottom of the fill port.

If oil spills from the fill port

when the axle differential is cool, it is overfull.

Allow oil to drain until no more drains out.

If the oil level is more than one

inch below the bottom of the fill port, refill axle differential with GO specified for the ambient temperature until level with

bottom of fill port.

Change the oil every 24,000 miles (38,616 km) or once every two years, whichever occurs first.

Drain

oil when hot after operation.

Back to Top