TM-9-2320-429-10 - Page 501 of 1096

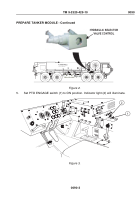

PREPARE TANKER MODULE - Continued

7.

Position tanker controls. (WP 0084)

8.

Connect SR1 and SR2 static cables (4) to vehicle being serviced and grounding

devices.

DRAIN EXISTING FUEL (DUST CAPS ON SERVICING HOSES)

WARNING

To prevent fire or explosion, do not allow smoking, flame, sparks, and hot

or glowing objects within 50 ft. (15 m) of vehicle. Read and follow all safety

precautions in FM 10-67-1. Failure to comply may result in injury or death

to personnel.

CAUTION

•

Do not run tanker pump without fuel in system or damage to fuel

pump and hydraulic motor may result.

•

Do not press accelerator during tanker primary fuel pump operation.

Engine speeds higher than 1500 rpm may cause damage to hydraulic

motor and primary pump.

NOTE

•

Refer to FM 10-67-1 for general operating instructions for tank

vehicles.

•

If equipment malfunctions, check that all steps of procedure have

been performed in proper order. If equipment still malfunctions, do

troubleshooting.

•

Tanker must be holding at least 300 gal (1136 liters) of fuel in order

to perform fuel hose evacuation.

•

There are two different models of tanker module covered. Newer

models of tanker modules have a rubber tie down strap to secure fuel

service nozzle (which is not normally removed between uses) in

stowage position. Those procedures are called out in drain existing

fuel (fuel service nozzles installed on servicing hoses) . Older models

use dust caps to cover the ends of both servicing hoses when not in

use. The procedures for these models are listed below.

1.

Disengage hose reel tension knob (1).

TM 9-2320-429-10

0090

0090-5

Back to Top