TM-9-2320-431-10-2 - Page 159 of 712

OPERATOR MAINTENANCE

BOOM RAISES OR LOWERS SLOWLY

INITIAL SETUP:

Equipment Condition

Vehicle setup for crane operations.

(Volume 1, WP 0106)

TROUBLESHOOTING PROCEDURE

BOOM RAISES OR LOWERS SLOWLY

TEST 1 - Does boom raise or lower normally after running engine for 20 minutes with

PTO engaged?

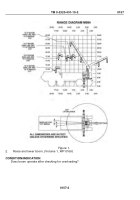

NOTE

Common problems that crane operators may see are:

1. Slow or abnormal operation.

2. Crane will not pick up load.

Common causes of problems are:

1. Cold hydraulic oil (slow operation).

2. Low engine speed (slow or abnormal operation).

3. Operating two craning functions at the same time (slow operation).

4. Load too heavy (will not pick up load).

5. Air in cylinder or hoist motor (abnormal operation).

Report all problems to field level maintenance.

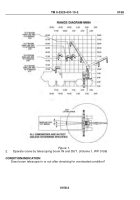

If outside temperature is 0°F (-17°C), hydraulic fluid may not flow easily.

1.

Start engine. (Volume 1, WP 0044)

2.

Set PTO ENGAGE switch to ON. (Volume 1, WP 0106)

TM 9-2320-431-10-2

0156

0156-1

Back to Top