TM-9-2330-238-14

CHASSIS, SEMITRAILER: 6-TON, 4-WHEEL M295A1; SEMITRAILER, VAN: EXPANSIBLE, 6-TON, 4-WHEEL M313; SEMITRAILER, VAN: SHOP, FOLDING SIDES, 6-TON, 4-WHEEL M447 AND M447C; SEMITRAILER, VAN: REPAIR PARTS, SHOP EQUIPMENT, 6-TON, 4-WHEEL M749; SEMITRAILER, VAN: REPAIR PARTS STORAGE, 6-TON, 4-WHEEL M750

TECHNICAL MANUAL; OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT MAINTENANCE MANUAL

JULY 1992

TM-9-2330-238-14 - Page 169 of 462

Equipment Conditions:

Tools/Test Equipment

(12.70 mm) monomum and 7/8 in. (22.23 mm) maxi-

mum. Adjust brakes if necessary.

TM 9-2330-238-14

Section VI. BRAKE SYSTEM MAINTENANCE

Page

Paragraph Title

Number

Air Coupling Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-94

Air Filter Maintenance (Early Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-88

Air Lines and Fittings Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-95

Air Reservoir Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-92

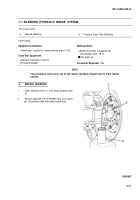

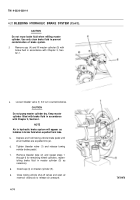

Bleeding Hydraulic Brake System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-73

Brake Backing Plate and Support and Adjuster Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-81

Brakeshoe Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-76

Hydraulic Lines and Fittings Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-86

Master Cylinder and Airbrake Chamber Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-84

Pushrod Travel Test and Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-71

Relay Valve Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-90

Wheel Cylinder Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-79

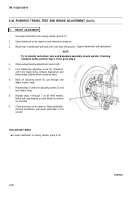

4-36.

PUSHROD TRAVEL TEST AND BRAKE ADJUSTMENT.

This Task Covers:

a.

Pushrod Travel Test

b.

Brake Adjustment

Initial Setup:

●

Semitrailer coupled to towing vehicle (para 2-10).

●

General mechanic’s tool kit

●

Hydrauiicjack

Personnel Required:

Two

●

Twojackstands

a. PUSHROD TRAVEL TEST

1.

With service brakes released, insert a small rod

(3) in one of two inspection holes (4) on airbrake

chamber (1), until rod contacts pushrod.

2.

Mark rod (3) at surface of mounting bracket (2).

3.

Apply service brakes and hold, insert rod (3) in

airbrake chamber (1) until it contacts pushrod,

then mark rod at surface of mounting bracket (2).

4.

Remove rod (3) from airbrake chamber (1) and

measure distance between marks, which indi-

cates amount of pushrod travel.

TA701975

4-71

Back to Top