TM-9-2330-326-14-P - Page 274 of 540

TM 9-2330-326-14&P

H-20

H-6.

TORQUE TABLE (Cont.)

STATED RANGE

MOST EFFECTIVE RANGE

0–200 lb-in.

(0–23 N•m)

50–150 lb-in.

(6–17 N•m)

0–600 lb-ft.

(0–813 N•m)

50–450 lb-ft.

(68–610 N•m)

0–170 lb-ft.

(0–23 N•m)

44–131 lb-ft.

(60–178 N•m)

15–75 lb-ft.

(20–102 N•m)

30–60 lb-ft.

(41–81 N•m)

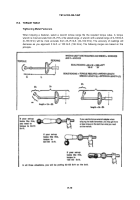

Installation and Torquing

Matching Nuts. Matching nuts require a minimum height (see page H-22) equal to the basic diameter

of the bolt. The same is true of tapped holes. In tapped softer materials, the depth of the tapped hole

should be 1-1/2 times the basic diameter of the bolt.

Thread Protrusion. In all installations, bolts, studs, and screws must extend through the nut at least a

length equivalent to two complete threads (see page H-22). This applies to both self-locking and plain

nuts.

Torquing Self-Locking Nuts. To obtain the correct recommended torque value on self-locking nuts, the

nut must be tightened until it is one turn from the beginning of seating. At this point, if the torque is

less than 1/3 of the recommended torque, it should be disregarded and the nut tightened to the

recommended torque value. If the torque is 1/3 or more of the recommended torque, it should be

added to the recommended torque. Example: The recommended torque is 50–70 lb-in. (6–8 N•m). The

torque at one turn from seating is 30 lb-in. (3 N•m). The correct torque wrench reading would be 80–

100 lb-in. (9–11 N•m).

Retorquing Fasteners. Procedures intended for installing metal fasteners can cause incorrect reading

when used to check or retorque already installed fasteners during maintenance. Before checking or

retorquing an already installed threaded fastener, first mark the fastener and its companion

components so the marks are in line. Second, back it off a 1/4 turn to loosen it. Torque it to the

specification with an even steady pull on the torque wrench. The marks should be in line; if not, the

marks will indicate the fastener was under or over torqued.

Standard Torque Charts. Standard torque charts have been established for dry and wet torque

conditions. Surface variations such as thread roughness, scale paint, lubrication (oil, grease, etc.),

hardening, and plating may alter these values considerably. The following are standard torque charts.

To find the grade of the screw that is to be installed, match the markings on the head to the correct

picture of CAPSCREW HEAD MARKINGS on the table. Manufacturer's marks may vary. These are all

SAE Grade 5 (3 lines):

Back to Top