TM-9-2350-275-BD - Page 58 of 223

TM

9-2350-275-BD

ENGINE

Procedural Steps (Cont):

6. The steer control differential is made from a magnesium alloy. Use plastic type

fillers or appropriate MIG or TIG welding equipment to make repairs.

7.

Record the BDAR action taken. When the mission is completed, as soon as

practicable, repair vehicle using standard maintenance procedures.

3-17. CONNECTING ROD OR ROD BEARING FAILURE

General Information:

Broken connecting rod or rod bearing failure will cause the engine to be inoperative,

normally with extensive internal engine damage. If the engine is not damaged where it

will no longer run, it may be operated under emergency conditions, using the following

procedures. The damaged cylinder can be isolated and continued operation is possible.

The lower portion of the connecting rod must be replaced on the crankshaft to maintain

oil pressure. Without the rod on the crank journal the oil will free flow from the oil

gallery causing excessively low oil pressure with resulting damage to other engine

components.

Limitation

●

Reduced mobility

Personnel Time/Required:

●

2

soldiers

●

4-6 hours

Materials/Tools:

●

Wood wedge

●

Engine oil and coolant

●

Lifting device

Procedural Steps:

1. Remove power pack.

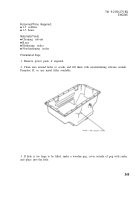

2. Remove oil pan to gain access to connecting rod bearing caps.

3. Remove the lower portion of damaged connecting rod, bearings and bearing cap.

3-16

Back to Top