TM-9-2815-220-24 - Page 1230 of 1563

TM 9-2815-220-24

CYLINDER VALVES AND ASSOCIATED PARTS REPAIR

0145 00

INSPECTION (Continued)

NOTE

Do not interpret termination of chrome plating on stem as indication

of a cracked valve stem.

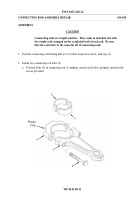

4. Measure outside stem diameters of exhaust (1) and intake (2) valves.

Replace valves that do

not meet specifications in the following table.

Location

Sizes and Fits of New Parts inches (mm)

Wear Limits

A

(exhaust valve stem)

0.5570 (14.1478)

0.5580 (14.1732)

0.5565 (14.1351)

B

(intake valve stem)

0.4975 (12.6365)

0.4980 (12.6492)

0.4970 (12.6238)

1

2

5. Lightly blue face of valve inserts (3 and 4) with Prussian blue (item 25, WP 0173) and place

valves (1 and 2) into position on valve seat insert.

6. Rotate valves (1 and 2) one-half turn on insert and check for Prussian blue contact.

Valve

must show full contact (360°), as indicated by Prussian blue transfer, to qualify as a

serviceable valve.

Valves that are not too badly damaged may be ground to be made

serviceable.

2

4

3

EXHAUST

INTAKE

1

WP 0145 00-2

Back to Top