TM-9-2350-238-20-2 - Page 28 of 495

CAUTION

TM 9-2350-238-20- 2

2-7.1 GENERAL PROCEDURES (CONT) .

(2)

Servicing.

This usually means drain -

ing and refilling units with oil and changing or

cleaning oil filters, fuel filters, and air

cleaners .

(3)

Tightening.

Tighten nuts, bolts ,

screws, and other types of fasteners with a

torque wrench to the value listed in th e

maintenance manual. Do not over tighten ;

this may strip threads and break off the par t

being tightened .

(4)

Repairing.

Repair includes inspecting ,

cleaning, preserving, adjusting, replacing ,

welding, riveting, strengthening, and othe r

tasks associated with putting parts in workin g

condition .

(a)

Inspect for burrs, cracks, gouges ,

or nicks .

(b)

Replace bent, broken, or strippe d

bolts, nuts, screws, and washers. Bolts ,

screws, and nuts may be loose if rust ,

chipped paint, or bare metal is around them .

Tighten loose screws, bolts, and nuts .

Replace missing parts .

(c)

Look for bad welds where chippe d

paint, rust, or gaps are present. Have ba d

welds repaired .

(d)

Look at electric wires for cracked ,

frayed, loose, discolored, or broken insulation .

Replace bad parts and tighten loose clamps

and connectors .

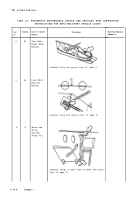

NOT E

When tightening fittings, alway s

hold fitting adapter with on e

wrench and tighten nut wit h

another wrench until snug .

Tighten

nut

around

1/6-turn

to

1/3-turn.

If

fitting

leaks,

unscrew

nut a full turn and retighten it. If

still leaking, replace leaking parts .

(e)

Look at hose, fluid lines, and tubes

for bends, wear, cracks, or leaks. Replac e

bad parts. Make sure all clamps and fittings

are tight. If a fitting leaks, tighten it .

Equipment operation is allowabl e

with minor leakages (Class l or ll) .

Of course, you must consider th e

fluid capacity in the item/syste m

being checked/inspected. When i n

doubt, notify your supervisor .

When operating with Class I or

Class II leaks, continue to check

fluid levels as required in your

PMCS. Class lll leaks must be

repaired .

NOT E

Fluid leaks affect vehicle status .

Learn the following classes o f

fluid leaks for unit PMCS .

Class l- Seepage of fluid (as indicated by

wetness or discoloration) not grea t

enough to form drops .

Class ll- Leakage of fluid great enough to

form drops but not enough to caus e

drops to drip from item bein g

checked .

Class Ill-Leakage of fluid great enough t o

(5)

form drops that fall from the item be-

ing checked. Class Ill leaks should be

reported to your supervisor or direc t

support maintenance .

Corrosion.

Check for signs o f

deterioration, rust, unusual cracking, soften-

ing, swelling, or breaking on entire M57 8

Recovery Vehicle. Become familiar with th e

four stages of corrosion listed below, an d

take the appropriate required maintenance ac-

tion outlined below .

Stage 1 - Red, black, or white corrosio n

deposits on surface wit h

etching or pitting. However ,

base metal is sound .

Stage 2 - Powdered granular or scale d

condition. Base metal is sound .

2-1 0

Change 1

Back to Top