DMWR-9-2815-220 - Page 135 of 1422

)

)

±

DMWR 9·2815±²20

5-12.

(Cont)

the crankcase, accordiNg to the locatIoN number stamped on the craNKcase

aNd cap.

The side of the beariNg cap marked

11FLY

E±D1² mUst face the rear

oF tHe cran³case´

riflA³

,±²l

³U8

J3o´A

c

Gµ

(4±

Apply a sMaLl aµouNt of O¶

30

eNg·ne oil¸

G¹ 9e to the threaded

area of each µaiN bearing cap stºd»

¼nstall a Plate wasHer on eacH pair

of ½·n bear¾ng studs.

¿nstaLÀ a slotted NUt on eacH ma·n Bearing stud

but do not tighten Nuts at this tiÁe´

²³´

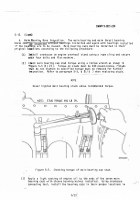

Âlace a surFace plate aNd dial indicator gage on cranKcase fÃaNge wIth

gage iÄdicator restINg oN eNd oF studÅ

ÆeasUre and record he·gHt

.

each

stud.

ÇorqUe tIgHten ÈiN bearÉNg stÊd nUts to

µ00

poUNd-iNches.

AËterNately tighten aÌl four nÊts on eacH Main bearing to a torque of

700-

82¶

poUndÍ·Äches./ÆeasUre tHe HeÎght of eacH stud after finaL

Ï

torque´

ÐHe difFerence betWeen tHe stÊd HeigHt beFore and after torQue t·ghteNIng

iNdicates stUd stretcH.

Ñor½À stud stretch is

0·019

to

0·0¸2

in.

Apply

addit¾onal torque to obta·Ä a stud stretch of

0·019

to

0·022¹

Òo not

exceed

0·024·

Ó¿F any stud has stretched Ôre than

0º02»

iN. at

¼00

.

poUndÕ¾Nches torqueÖ it mUst be replaced.

Refer to paragra×h

5½5,

d

(5/ 6±

When repÀac·ng studs.

l3±&0a²/³C1.´

¾¿À

ØNstaÀL the

14

engIne craNKcas

µ

s iN tHe hoLes provided throÊgh tHe

crankcase and main beariNg ca

Ù

s.

ÚquaÀize the extension of the threaded

portions of tHe rods onÛ oF the craNkcase.

Apply a sMalL aµouÄt

of ÜE

Á0

engine oilÝÞß to tHe threaded portions oà each rod.

ánstaâl a plate Washer

ã

aNd a

9/16

slotted Nut on each eNd of the rodsä

TA034±0²

åIæurç

5½Â¹

èHecKéng ênsÎde diaëeter of ìain and MaiN thrust bear·ngsí

5/Ã4

·.

Back to Top