DMWR-9-2815-220 - Page 136 of 1422

DMWR 9·2815-220

5-12.

(Cont)

(7±

Starting at the main thRust bearIng cap, wIth AId of aN assIstaNt to holD

the Nuts on the opposIte side of craNkcAse²

³lteRNAteLy

tIghten AlL MiN

beARINg cAp engi´e cRANkcAse roD nuts to 640 pouNd µinches toRque¶·/

(8±

Check the Inside Diameter of the mAIn beAr¸ng cAps and the mAI´ thrust

bearing cAp with A d¹AL boRe inDicAtor as showN In fIguRe 5º6 (5»¼

±

agaINst the LImits specIFIed ½n O¾P's 87¿À

Á

ÂÁ

Ã

{5»

8

Ä

Å aND 732ÆÂ7¼Ç

)

5

ÈÉ

7

}

.

.

(9)

Êf BeARings ARe to Be

ReuseDË

DisassemBÌe caps aND INstaLL tHRust aND

mAiN BeaRiNg sLeeve hALvesÍ

ÎpreaD a thIn coat of ÏRussiAN blueÐ

ÑÊÒµP-30À0ÓÐ over steeL BAcks of upper A´d loweR ÔAin sleeve beArIng

halves to show the sLeeve beaRIng coNtact suRfAce with the ÕaiN Beari´g

boRe I´ crANkcase¶

¾nstaLL BeARings In theIR oRIginaL location iN cRa´kÖ

case aND mAIn ×eARing cAps.

NOTE

ØAIN BeARIng sLeeve haLves must be instAlleD in theIR orIgINAl locAtion

when they aRe to BeÙ ReuseDÍ

Use new BeaRIngs when A visual inspectIoN

iNDÚcAtes beArings are uNseRviceAbLe¶

ÛÜ0±

Check cLeaRANce BetweeN upper bearINg fLA´ge ANd crANkcaseÍ

ÊNstAlL

upper mAIN thRÝst sleeve BearIng Into Þo. Â mAI´ Bearing seAt of craNkß

case.

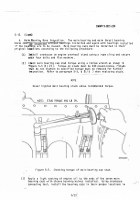

Øeàsure cLearAnce Between BeAri´g fLange AND cRankcAse usiNg

feeleR gAge Ûfág. 5µâ±

±

» 25±ã

CLeArAnce shouLD be 0.00Â to äå008

æ

InchÍ

SLeeV±

B²ARInG

\

±'

/

.

'³´-µ

-

-

²

¶

³

\

I

i

tA034301

çIgère 5-éê

CheckIng cLearANce beTWeen beArINg flA´ge A´d crANkcAseë

À»25

Back to Top