DMWR-9-2815-220 - Page 165 of 1422

·.

±

²³

-

±

²

.

·-±²³

³´µ¶·¸

_

´.±

¹

µ

¹

DMWR 9-2815±220

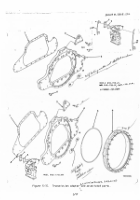

5-13.

(Cont)

(b±

DimensIonal changes²

To detec³ diMNsioNal chaNGes caused by weldiNG

repa´r, precµsely ¶asure craNkcase a³ severaL Key posI³Ions dependING upoN ³he

loca³io· of ³he repaIr¸

For repair ³o side walls, measUre ³he posI³IoNs outl¹ned

beLow²

ºe³³ers in parentheses be»ow refer ³o d¼¶nsioN iden³I½Ica³Ions used iN

¾fiGUre ¿À1Á (Â/Â0 ± UNÃess otheRise iNdica³ed.

²

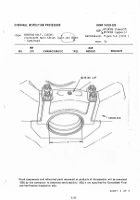

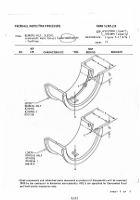

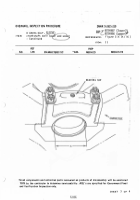

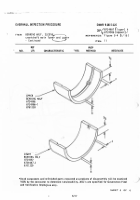

Across ³he Äain beariNG cap sÅppor³ We ÆchIned sur½aces JÇiGÈ

Â-1ɱ (

Ê

/

SO

±

•

2

Across ³he Inside of ³He craNKcase at ³he jÅNc³ioN of the side ËaÌL

aNd the oÍl paN rail ÎD±Ï

3

FroÐ oil pan raIl ½ace to main bearinG cap support face (ѱ²

4

ÒroÐ cylinder moÅNtiNG decK ³o cranÓsha½³ beariNG sUpport bore cen³erÔ

LiNe ÅsinG a sUI³able plUG or bore iN the cranKcase bearinG bore (Õ±²

Th¼s measUreÔ

meNt shall be within

8.37±-8²369

Inches²

Â

ÖiL pan raIl shaLl be ½la³ withIn ×.×Á× INch wheN all Øour corNers

are oN thE same pLaNeÏ

(c±

Öther rePaIr locatIonsÙ

Úor repair in o³her »ocationsÛ ÜeasurÝ in the

appropria³e Þoca³ßons to ànsUre táat crI³Ical dimensions are heâd.

ãecorä dimensions

å

½ær fųure Use²

)

³´eµ¶

c

t

·¸¹

D º»¼½¾

TA0¿ÀÁ¿

çiGÅre èéÉɸ

êoInts o½ ¶asUre ½or checëInG craNìcase

be½ore and after weldinG repaIrÏ

Â/íî

Back to Top