DMWR-9-2815-220 - Page 159 of 1422

OVERHAUL INSPECTioN PR±CEDURE

dMWR 9-2815-220

Qlp,8724987

lower

±)

BEARING HLF, S±E²V

²

872±986

upPer

ITEM:

REFERENCE±

figure

5-4 (² /16

)

cranksha³t min ´o

³

er

ItEm²

³´

R

INSP

NO.

LTr

CHArACtErIS±Ic

*AoL

MEtHOD

rEQISI±e

l

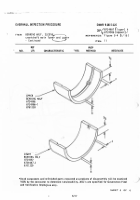

Cracks

0.0

VisUaµ

None ¶·lowed

2

Scratc¸es,

n¹cksº

2.²

VisUa»

No¼e ¶lloweD

gouges, or raised

Mt¶

µ

on contact

sUr³aces

3

Se½arat¹o¼ o³

¶ ²

V¹sUa¾

¿one a··oweD

beari¼g Mta

µ

.´µ

³rOÀ beari¼g

4

ÁÂtt¹¼gà ga··¹¼gº

scori¼g or DÄs-

coloratio¼ o³

beari¼g sur³ace

5

Å

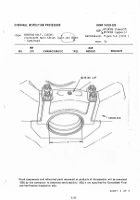

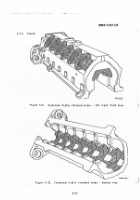

I¼side DiaMter o³

)

Æi¼ bearing asseÀÇ

bleÈ at ProÉer

Torque

Sta¼darD

·

µ.0

Êasure

˹aÌter Àust be

Part ¼o.

872±987

¼o greater t a¼

a¼d

872±986

4

² 258³

inches

Í

.,4²

0¸0030

U¼dersize

-

µ¹0

ÎeasuÏÐ

ÑiaÀeter Àust be

½art no.

8724987·³

¼o greater tha¼

a¼Ò

872±986·

·

45 ¹nc¸es

J·;6³´

0º0µ00

u¼dersiZe Ó

µ»0

Îeasure

ËiaMter Ôust be

Part ¼o.

876µ329

no greater tha¼

a¼Ò

876¼½28

´ µ

i¼ches

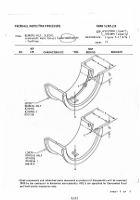

6

B

Õ¸ickness o³ Ö¼

'-: 4

bearing hal³ at

ce¼ter

×ta¼DaØD

¶

µ.0

ÎeasÙre

˹Àe¼sÂo¼ ÚUst Ûe

½art ¼oÜ

872±987

¼o

³

ess tha9

Ý

Þ

µ

Í

and

8724986

¶·

inc¸ß

i¸¹º»s

·¸¹

)

•Used components aND refinished pArTs reCovereD as produC±s oF DisasseMbly will be exaMineD

100%

By tHe Con²raC±oR ²o De±ermIne se³ViCeabili´y. µOL's ¶re sPec·F·eD For GovernMent ¸ina¹

¶ºD »e¼·F·Cat·oN ½nspeC±ion oº¾y¿

SHEET

l

Of

¾

¿/ÀÁ

Back to Top