LO-9-2350-247-12 - Page 11 of 43

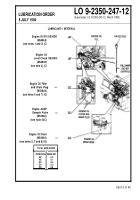

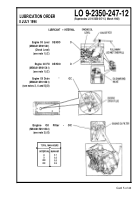

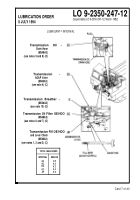

LUBRICATION ORDER

LO 9-2350-247-12

8 JULY 1994

(Supersedes LO 9-2350-247-12, March 1982)

KEY

EXPECTED

REFILL

TEMPERATURES*

LUBRICANTS

CAPAClTY

+40°F

0°F

INTERVALS

(APPROX)

Above

to

to

32°F

-10°F

-65°F

OE/HDO (MIL-L-2104C)

LUBRICATING OIL,

AF -

After

OR OEA (MIL-L-46167)

INTERNAL COMBUSTION

S - 150 Hours,

ENGINE

1,500 Miles

Transmission

16 qt.

OE/

OE/

OEA

or Semi-annually

HDO-10

HDO-10

OC - On Condition

For Arctic Operation Refer to FM 9207

NOTES

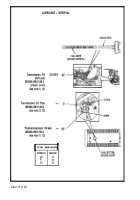

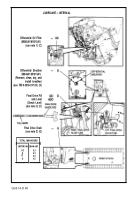

1. TRANSMISSION (M548A1/M1015A1). After opera-

marks on gauge rod (refill capacity 16 quarts). After filling

tion, check transmission oil level for between ADD and

transmission, check for oil leaks with engine running.

FULL marks on gauge rod. With engine disconnect

Recheck oil level.

engaged, start and run engine at 800 rpm for 3 to 5

minutes with shift lever in 2-3 and brakes locked to allow

WARNING

transmission oil to reach all normal operating tempera-

Dry cleaning solvent PD-880 is toxic and flam-

ture. Move shift lever through all RANGES to assure

mable. Death or injury may result. Always use in an

complete oil circulation. Return shift lever to N and check

open area with good air low, away from sparks,

transmission oil level with engine operating at 1,500 rpm.

heat, or flames. Wear protective goggles and gloves.

Add oil (OE/HDO) as required. Every 25 hours of opera-

Do not breathe vapors. Avoid contact with skin,

tion or 30 days (whichever comes first), obtain a sample

eyes, and clothes. If you get dizzy while using

of oil and send this sample to the nearest AOAP Labora-

solvent, breathe fresh air and get medical help. If

tory. To obtain oil samples from AOAP valves:

solvent gets on hands, wash them. If solvent gets

in eyes, flush eyes with fresh water and get medical

(1) Unlatch and raise grille behind cab on left side of

help immediately. Keep fire extinguisher nearby.

carrier.

(2) Take oil sample of transmission oil, using proce-

NOTE

dures given in TB 43-0106.

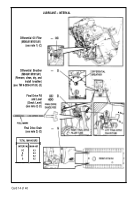

If transmission has been filled with (PE) oil (preserva-

tive engine oil) by the manufacturer or at time of

CAUTION

overhaul, leave this oil in transmission until first

Do not access AOAP valves from the power plant

scheduled oil change. Maintain operating oil level by

rear access panel opening as serious injury could

adding ap Iicable grade of oil (OE/HDO). When first

result from air brake compressor belts.

schedule oil change is made, refill transmission

with applicable grade oil (OE/HDO). OE/HDO is equiva-

When AOAP Laboratory support is not available, drain

lent to PE-10-1.

transmission oil every 150 hours, 1,500 miles, or semi-

annually. Drain only when hot after operation. To drain,

When using On Condition for the transmission oil,

remove hull bottom access cover (TM 9-2350-247-20)

the transmission oil filter should be changed at hard

and transmission drain plug. Catch oil in suitable con-

time intervals

tainer. Allow oil to drain thoroughly - 1 hour if time

permits. Examine oil for evidence of overheating, foreign

matter, and metallic particles. If metal chips or filings are

found on plug or in oil, notify your supervisor. Clean and

install drain plug, and INSTALL ACCESS COVER SE-

CURELY. Service filter (see note 2). Add oil (OE/HDO)

as required to bring oil level between FULL and ADD

Card 11 of 40

Back to Top