TB-9-2320-335-13-P - Page 130 of 680

TB 9-2320-335-13&P

3-48

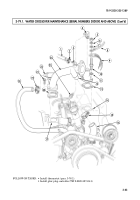

3-80.3. GEARED FAN DRIVESHAFT MAINTENANCE (SERIAL NUMBERS 300000 AND ABOVE)

This task covers:

a. Removal

c.

Installation

b. Inspection

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix B, Item 1)

Maintenance and repair shop equipment:

automotive (Appendix B, Item 2)

Materials/Parts

Sealing compound (Appendix C, Item 71)

Manual References

TM 9-2320-387-10

TB 9-2320-335-13&P, Appendix E

Equipment Condition

• Hood raised and secured (TM 9-2320-387-10).

• Upper fan shroud removed (para. 3-62.2).

Maintenance Level

Unit

NOTE

Rotate crankshaft pulley accordingly to access capscrews.

1.

Remove six capscrews (1) and geared fan driveshaft (8) from geared fan drive (6).

2.

Remove four capscrews (7) and geared fan driveshaft (8) from coupler plate (3).

NOTE

• Rotate crankshaft pulley accordingly to access capscrews.

• Hold alternator clutch pulley adapter to keep crankshaft from

rotating.

3.

Remove four capscrews (4) and coupler plate (3) from lower crankshaft pulley assembly (5).

4.

Remove four grease fittings (2) from geared fan driveshaft (8).

Inspect grease fittings (2). Replace if damaged.

1.

Install four grease fittings (2) on geared fan driveshaft (8).

NOTE

• Rotate crankshaft pulley accordingly to access capscrews.

• Hold alternator clutch pulley adapter to keep crankshaft from

rotating.

2.

Install coupler plate (3) on lower crankshaft puller assembly (5) with four capscrews (4).

3.

Install geared fan driveshaft (8) on coupler plate (3) with four capscrews (7).

4.

Apply sealing compound to six capscrews (1). Install geared fan driveshaft (8) on geared fan drive (6)

with six capscrews (1).

c. Installation

b. Inspection

a. Removal

Back to Top