TM-5-2330-325-13-P - Page 169 of 648

Table 1.

Operator Preventive Maintenance Checks and Services (PMCS) Procedures - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

25

Before

Hydraulics

Wipe connectors clean, connect hydraulic lines from

gooseneck to towing vehicle (WP 0005), and check for

leaks.

Any Class III leaks

are evident.

26

Before

Gooseneck

Check gooseneck operation (WP 0005).

Gooseneck does not

operate correctly

(WP 0005).

27

During

Hydraulics

NOTE

If semitrailer will not be used for 72 hours or

more, lightly coat exposed cylinders with

grease.

Check for leaks.

Any Class III leaks are

evident.

28

During

Gooseneck

Check gooseneck operation (WP 0005).

Gooseneck does not

operate correctly

(WP 0005).

29

During

Gladhands

Check for leaks at gooseneck gladhand connections.

Any leaks are evident.

30

During

Brakes

Operate semitrailer brakes and ensure brakes at all six

wheel positions are operating properly.

Semitrailer brakes

inoperative.

31

After

Tires

Check tire pressure when tires are cool.

Any tire is flat, missing, or

unserviceable.

32

After

Wheels

Check wheels for damage. Check for debris or foreign

objects lodged between wheels.

A wheel is damaged or

unserviceable.

33

After

Lug Nuts

Check lug nuts for tightness and ensure all lug nuts

are installed.

A lug nut is missing.

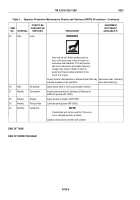

34

After

Hub Mileage

Meter

Inspect hub mileage meter (Figure 4) for damage. Note

mileage and check for proper operation.

466-0027a

Figure 4.

Hub Mileage Meter Check.

TM 5-2330-325-13&P

0033

0033-5

Back to Top