TM-5-2330-325-13-P - Page 167 of 648

Table 1.

Operator Preventive Maintenance Checks and Services (PMCS) Procedures - Continued.

ITEM

NO.

INTERVAL

ITEM TO BE

CHECKED OR

SERVICED

PROCEDURE

EQUIPMENT

NOT READY/

AVAILABLE IF:

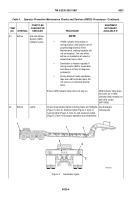

16

Before

Tool Box

Check tool box cover for proper operation

and serviceability.

17

Before

Deck Planking

Inspect planking (Figure 2, Item 1) for damaged or

broken boards.

Planks are missing.

18

Before

Deck Hardware

Check for missing or damaged bolts and fastening

hardware (Figure 2, Item 2).

19

Before

Outriggers

Check for proper operation of folding outriggers

(Figure 2, Item 5).

Outrigger load prohibited

if any outriggers or

boards are unserviceable.

20

Before

Tiedown Points

Check D-rings (Figure 2, Item 3) and chain slots

(Figure 2, Item 4) for serviceability.

Tiedown points are

damaged or unusable.

21

Before

Chains and

Loadbinders

Check chains (Figure 2, Item 6), load binders

(Figure 2, Item 7), and other tiedowns for serviceability

and proper quantity.

Loadbinders or chains not

sufficient for proper

securing of payload.

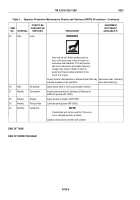

466-0028

1

3

2

5

4

6

7

Figure 2.

Deck Planking, Outriggers, and Tiedowns.

22

Before

Brakes

NOTE

Any drop in air pressure will indicate an

air leak.

Check for leaks in air brake system by shutting off

truck tractor engine when air pressure is at maximum.

Observe air pressure gage for 1 minute.

Any leaks are evident.

TM 5-2330-325-13&P

0033

0033-3

Back to Top