TM-5-2350-262-20-1 - Page 476 of 776

TM 5-2350-262-20-1

Change 3

4-127

Note

Although the Bilge Pump is considered

Not Mission Essential and will no longer

be supported with spare and repair parts,

this task contains maintenance procedures

For Your Information Only.

See TB 43-

0001-62-7 (dated Oct 98) for Instructions

to Isolate and Disconnect a Non-

Functional Bilge Pump.

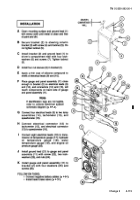

A

Remove two scews (1), lockwashers (2), and

washers (3) from bracket (4).

Remove bracket (4)

from driver’s compartment wall.

Discard

lockwashers (2).

B

Remove screw (5), lockwasher (6), and clamp (7)

from driver’s compartment wall.

Discard

lockwasher (6).

C

Disconnect leads (8) and (9) from leads (10) and

(11).

DISASSEMBLY

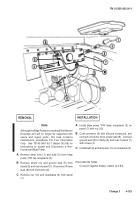

A

Remove clip (12) and roller guide (13) from switch

(14).

B

Remove nut (15), washer (16), switch (14), keyed

washer (17), and nut (18) from bracket (4).

C

If switch (14) is not to be reused, remove electrical

connectors from circuit leads (8), (9), and (19).

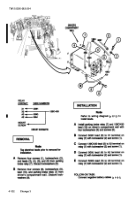

ASSEMBLY

Note

•

If installing new bilge pump “ON” switch,

perform steps A through F.

•

Refer to wiring diagram (p FP-3) to

install electrical connectors and marker

bands.

A

Install terminal assembly (20), sleeve bushing

(21), and connector shell (22) on 1 circuit lead

(11).

B

Install 450 marker band (23) on 1 circuit lead (11).

C

Install electrical contact (24), slotted washer (25),

and connector shell (26) on 3 circuit lead (9).

D

Install 450 marker band (27) on 3 circuit lead (9).

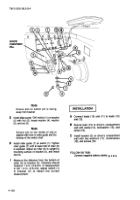

REMOVAL

E

Install terminal assembly (28), sleeve bushing

(29), and connector shell (30) on 2 circuit lead

(19)

F

Install connector shell (31) and end seal plug (32)

on 2 circuit lead (19).

Back to Top