TM-5-3805-254-14-P-2 - Page 270 of 894

ELECTRICAL

TRUCK SERVICE MANUAL

4.

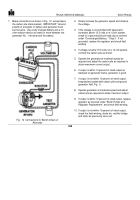

Connect battery to charger unit in series, connecting

positive terminal outlet from the supply line to the

positive terminal of the first battery.

Connect the

negative terminal of the first battery to the positive

terminal of the second battery and so on through the

number of batteries being charged.

(Do not exceed

the capacity of the charging equipment in the

number of batteries being charged at one time.

)

The last battery must have its negative terminal

connected to the negative outlet of the charging unit.

5.

Adjust charging rate in amperes to the lowest normal

charge rate of the smallest size battery according to

the accompanying chart (B).

Batteries should

remain on charge for a period of time sufficient to

obtain normal voltage and specific gravity readings

of each cell.

Required length of time will vary from

12 to 48 hours, depending on state of discharge at

time battery was placed on charge and the rate of

charge.

Temperature readings should be taken frequently to

prevent the electrolyte temperature from exceeding

125

°

F at any time.

If temperature does rise above

125°F, the charge rate should be reduced to allow

electrolyte temperature to drop below 125°F.

6.

Battery voltage is determined by normal electrolyte

temperature of 80

°

F.

Voltage readings are to be

taken while the battery

is on charge at the normal rate as specified in Chart

B.

Number

Normal

Battery

Volts

of

Charge

Plates

Rate (Amps)

1424X

6

99

15

CHART B

The battery voltage of a fully charged battery on

charge at the normal rate should read as shown in

Chart C.

Temperature

6-Volt-Battery

80

°

F

7.5 -7.8 volts

100°F

7.2 -7.8 volts

110°F

7.05- 7.65 volts

120

°

F

6.9 -7.5 volts

CHART C

A battery is fully charged when battery

voltage

values are as shown in Chart C and there is no

further rise in voltage over two successive readings

taken at one-half hour intervals.

7.

Add water as necessary; disconnect the batteries

from charging line; replace vent plugs; wash and dry

tops of batteries and return to service or the storage

rack.

Putting Dry Charged Batteries into Service

Dry charged batteries can be used immediately after

activating.

Prepare dry charge battery for service as

follows:

1.

Remove or destroy any sealing device used to close

or restrict the vent openings.

2.

Fill the cells 1/4 to 1/2 inch above the separators or

to the indicator level with sulphuric acid.

3.

The battery is now ready for use.

If the vehicle is to

be driven considerable mileage after battery

activation, no boosting charge is required.

However,

if it is not driven as noted above, a boosting charge

266

Back to Top