TM-5-3805-254-14-P-2 - Page 261 of 894

ELECTRICAL

TRUCK SERVICE MANUAL

Slip Ring Servicing

If the slip rings are dirty, they may be cleaned and

finished with 400 grain or finer polishing cloth.

Spin the

rotor and hold the polishing cloth against the slip rings

until they are clean.

NOTE:

The rotor must be rotated in

order that the slip rings will be cleaned evenly.

Cleaning

the slip rings by hand without spinning the rotor may

result in flat spots on the slip rings, causing brush noise.

Slip rings which are rough or out of round should be

trued in a lathe to .002 inch maximum indicator reading.

Remove only enough material to make the rings smooth

and round.

Finish with 400 grain or finer polishing cloth

and blow away all dust.

Bearing Replacement and Lubrication

1.

Remove retainer plate screws, retainer plate

assembly, gasket and collar.

2.

Press bearing from end frame.

3.

Remove retainer plate and felt washer.

4.

Install retainer plate and new felt washer.

5.

Press bearing in with sealed side away from grease

reservoir.

6.

Fill grease cavity one-quarter full with Delco-Remy

lubricant part number 1948791.

7.

Attach gasket and retainer plate assembly to end

frame using new retainer plate assembly.

The bearing in the slip ring end frame should be

replaced if its grease supply is exhausted.

No attempt

should be made to relubricate and reuse the bearing.

To

remove the bearing from the slip ring end frame, press

out with a tube or collar that just fits inside the end frame

housing.

Press from the outside of the housing towards

the inside.

To install a new bearing, place a flat plate over the

bearing and press in from the outside towards the inside

of the frame until the bearing is flush with the outside of

the end frame.

Support the inside of the frame with a

hollow cylinder to prevent breakage of the end frame.

Use extreme care to avoid misalignment or otherwise

placing undue stress on the bearing

If the seal is separate from the bearing, it is

recommended that a new seal be installed whenever the

bearing is replaced.

Press the seal in with the lip of the

seal toward the rotor when assembled; that is, away from

the bearing.

Lightly coat the seal lip with oil so that the

shaft will slip into the bearing more easily.

REASSEMBLY

Reassembly is the reverse of disassembly.

To install the slip ring end frame assembly to the

rotor and drive end frame assembly, remove the tape

over the bearing and shaft and make sure the shaft is

perfectly clean after removing the tape.

Insert a pin

through the holes to hold up the brushes.

Carefully

install the shaft into the slip ring end frame assembly to

avoid damage to the seal.

After tightening the thru bolts,

remove the brush retaining pin to allow the brushes to fall

down onto the slip rings.

When installing the drive pulley on the alternator, the

pulley nut must be torqued to 4060 foot pounds.

If not

properly tightened, it is possible that the nut and pulley

could loosen and slip on the shaft or even come off

during operation.

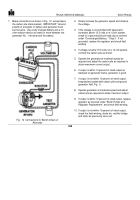

To assist in tightening the pulley nut, a 5/16 inch hex

hole is provided in the end of the shaft for holding with an

Allen wrench.

Also a special 15/16 inch socket wrench,

Fig.

11, which is applicable to the nut, is available from

the Snap-On Tool Company.

This special 1/2 inch drive

socket wrench is designed with a cutout to receive the

Allen wrench and may be used in conjunction with a

torque indicating wrench.

Where desired, a length of 3/8

inch pipe may be applied to the Allen wrench to provide

additional leverage for the holding effort.

The special 15/16 inch socket wrench, Fig.

11, is

available from your local Snap- On representative under

their number S-8183.

Back to Top